Inventory is one of the essential sources of revenue for a company. What management techniques to tool for inventory is a question for companies to consider. Various technologies are available in the market which is effective for inventory management. These technologies include a Perpetual inventory system, Periodic inventory system, Barcode system, and Radio Frequency Identification (RFID) inventory system. Next, I will focus on RFID inventory systems, and I hope this will help you in your selection.

What is Inventory?

As the name suggests, inventory is the actual storage of the current enterprise project. Selling the produced inventory is an essential source for the company. It is thus one of the most critical assets of a company.

The inventory’s role is to prevent economic losses caused by temporary production interruption. It can also shorten the delivery time when there is enough inventory.

Managing existing inventory prevents economic losses due to stock-outs or stock accumulation.

4 Types of inventory management

Inventory management manages the number of goods in the logistics process. It solves the conflicts that arise between supply and demand.

The company needs to forecast, plan and execute the act of replenishing the inventory according to the external demand. The execution of this replenishment is also controlled.

It is necessary to determine how to order when and how much to order on time. And if you want to know this information, you must manage the inventory.

Operators can choose different inventory management techniques depending on the company’s inventory needs.

Perpetual Inventory System

A perpetual inventory system, as the name implies, keeps track of existing inventory on an ongoing basis. Inventory levels are updated as companies buy and receive new inventory. Business returns are also recorded in the inventory account.

To use a perpetual inventory system, you must purchase specialized inventory management software or a POS system.

There are many benefits to choosing a perpetual inventory management system. It provides businesses with an accurate and up-to-date view of their inventory levels. It can help businesses order the correct amount of inventory.

It also has a pronounced disadvantage. This disadvantage is that it requires investment in both technology and software to execute. This disadvantage is more like an investment for companies with high inventory levels. This investment can help companies save time in tracking inventory. It can also optimize existing inventory management technology. But for smaller businesses, this can be an expensive expense. So for different businesses, the pros and cons are different.

Periodic Inventory System

A periodic inventory system tracks inventory at the end of the accounting period. It can be weekly, monthly, or even quarterly or annually.

It does not require the purchase of asset management software. All inventory information that needs to be recorded has to be performed manually.

The way it calculates the cost of goods sold is simple.

Cost of Goods Sold (COGS) = Opening Inventory + Inventory Purchases – Closing Inventory.

It is suitable for businesses that do not need to know precisely the inventory level and sell only a small amount of goods. An example is a small jewelry store.

It is not suitable for businesses with a large number of physical assets. The manual recording has a very high error rate and takes considerable time. As a result, it is easy for criminals to exploit loopholes and cause incidents such as theft and loss. It also does not provide up-to-date inventory information.

Barcode System

The barcode system is used to identify each product sold by using some numbers. The reader can get information about the item by recognizing the barcode number. This information includes item location, weight, and inventory.

Barcodes generally come in two forms. Barcodes are generally available in two forms, Universal Product Code (UPC) and Stock Keeping Unit (SKU). UPC is GS1 compliant. It is a unique code associated with a specific item. SKUs are used for internal control by each retail store and are created by them. SKU creation information can include store location, item size, and color.

Operators can use the barcode system in conjunction with a perpetual inventory system. The staff scans the barcode when an item is sold or moved into the store. This information is synchronized and uploaded to the inventory management software. It will automatically update the inventory.

This system is not suitable for businesses with a small number of items because it requires a relatively unreasonable cost.

It is suitable for companies with high inventory levels. In their view, the barcode inventory system may be a welcome addition. Its use helps companies to get the most accurate inventory data. It dramatically reduces the incidence of manual system errors.

RFID Inventory System

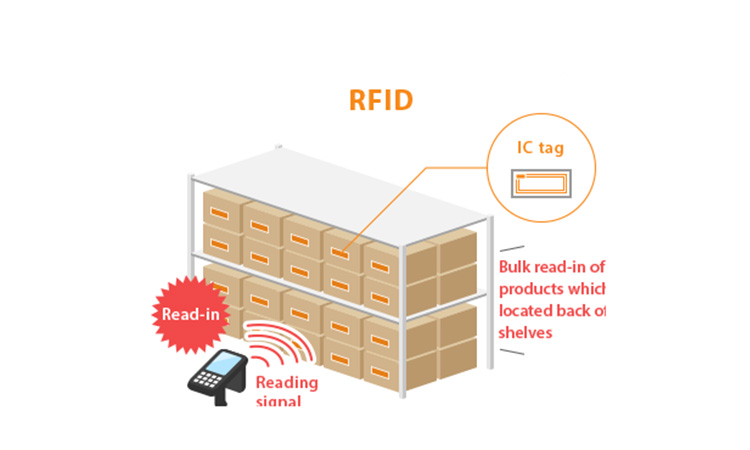

RFID inventory system is introducing RFID technology based on existing inventory management. It achieves the desired management purpose by attaching RFID tags to existing physical assets.

It enables automatic data capture of assets in a range of operations. These operations include arrival inspection, inbound and outbound storage, etc.

The system will keep tight control on all aspects of inventory management. It ensures the accuracy of the data entered in its process.

It can scan multiple goods in a pallet at a time to improve efficiency. It will deliver the actual data of the inventory to the company in time to make a reasonable allocation.

RFID programming can also manage goods’ batch and shelf life by entering them into RFID tags.

It can track all items, whether raw materials, parts or all other materials.

It can provide companies with detailed information about inventory levels. This information includes quantity, model, color and size, etc.

The system will help businesses to eliminate inventory problems. It can improve the security of their retail store operations.

How does an RFID Inventory Management System Work?

Usually, companies use active or passive RFID tags for inventory management. The basic workflow of active and passive RFID tags in a warehouse is the same, except for the difference in the way they are powered.

RFID tags that store cargo information is affixed to individual shipments before they arrive at the warehouse. When a shipment arrives at its destination, the operator can scan the tag to obtain information about the shipment.

These readers are usually placed in the receiving and storage areas. Radio waves transmit the data to the readers as the goods enter the warehouse. The readers are then uploaded to the RFID inventory tracking management system. The staff can view and modify the data and perform operations such as real-time asset counts.

RFID for Inventory Management Pros and Cons

Effectively improve work efficiency and reduce labor costs. RFID can read RFID tags from a distance without a line of sight. It means the process can be carried out even when staff is not on site. It also allows multiple readings at once. It means that it can scan many items simultaneously, which is much more efficient than scanning them one by one by staff. Using RFID for inventory management can reduce the labor cost of hiring personnel and shorten delivery times.

RFID tags have more storage space. It can store more data than a barcode. The reader scans the barcode to get the essential information about the item. However, it does not store much information. RFID tags can store a large amount of data inside the chip. It also allows different types of data to be stored. The data stored on the tag can be read and used by the staff through the reader. There is no need to connect to other network database platforms in this process.

RFID tags provide accurate time of entry and exit. RFID readers are set up at the entrance and exit of the warehouse to record the data of goods entering and leaving in real-time. Through the data uploaded to the RFID inventory system by the reader, the staff can know when the goods enter the warehouse and when they leave.

RFID inventory systems not only improve accuracy and efficiency but also increase security. , companies can restrict access to inventory items. It can also track the movement of items by using RFID tags. This helps reduce theft and vandalism. This is because only authorized personnel can have access to inventory items

RFID tags can help you optimize your operational strategies. RFID provides real-time inventory data. Using barcodes requires frequent scanning to obtain the corresponding data. Operators get information on consumer movement by viewing data on the RFID inventory system. Look at this data to see where items sell well and which consumers rarely buy. Because the data is updated in real-time, the inventory information is always new. Operators can frequently reconfigure inventory and adjust operational strategies.

It is expensive. There are three types of RFID tags, active, passive, and semi passive RFID tags. They are priced differently. In particularActive RFID tags are not only expensive per unit, but the internal battery is non-removable. It means the tags have a limited life span and need to be replaced at intervals of several years. Passive RFID tags are much cheaper, but they are not as durable. If you plan to use RFID tags to track every item stored in your warehouse, you’ll need to prepare a significant budget.

RFID tags are not yet standardized. Depending on the industry using the tags and the manufacturer producing them, the shape and data format of the tags can vary. There can even be differences depending on the country in which they are located. If you want to track your inventory internationally, your cost budget needs to be much higher. You will need to deploy the appropriate system in different locations as appropriate.

Not suitable for use in metallic or liquid environments. However, the reader does not require someone to be present during the tag reading process. However, this does not mean it can work without interference. Assuming that there is a lot of liquid or metal between the tag and the reader, the reader will have difficulty doing its job. In the case of interference by them, the error rate will be higher.

You may need more time to manage the data. RFID tags can store a lot of data, but much of it may be useless to you. It will take longer to process the data or purchase the appropriate server configuration. You may also overlook important information in the process of processing this data.

Properly implementing an RFID inventory system is key to ensuring accuracy and efficiency. Companies must implement the system correctly to avoid inaccurate data and inventory loss. In addition, RFID inventory systems may not work in all environments. The system relies on radio frequencies to track and monitor items.

RFID inventory system do not apply to everyone. Businesses with extensive physical inventories want to improve their existing tracking means. RFID can be effective in reducing business operating costs and improving work efficiency. But it may not be as necessary if you only need to manage a small factory or warehouse. When considering creating or adding an RFID inventory tracking system to your business, it is vital to understand the pros and cons. It may help you find a more suitable technology.

How much does an RFID Inventory System Cost?

Companies need to know the cost of implementing technology before they update themselves. It is an expensive cost. One of the highest initial costs is the buy of equipment. This equipment includes readers, antennas, cables, etc.

Let’s take a passive RFID inventory management system as an example. Assume that a reader costs about $1,000. We add cabling and other costs that may be incurred (such as the need for Power over Ethernet for operation), which could be as high as $3,000 each. However, if an active RFID inventory management system is used, the equipment cost may be relatively cheaper by a factor of 10. It is because it uses readers that may not be as demanding.

Companies also need to consider additional upfront costs. These costs may include facility modifications and conversion management software. These costs are not fixed and can vary significantly from case to case.

It also has ongoing costs. These ongoing costs include purchasing RFID tags, licensing, and post-implementation maintenance. Most businesses will use passive RFID inventory management system because the cost of tags is relatively low. Common passive RFID tags typically cost between 5 – 15 cents each (the price will vary depending on the quantity purchased). Passive RFID tags with special features can cost a little more. These unique features may be to prevent interference from metal objects, etc.

Active RFID tags will be relatively expensive, typically between $5 – $15. It is 100 times more expensive than passive tags because it contains a battery and can have more housing design.

Perhaps every inventory management technology on the market helps you keep track of your inventory. It has been proven that using RFID inventory system can increase inventory accuracy by up to 13%. It is very beneficial for specific retail industries and large warehouses. However, it is not suitable for all businesses.

About RFID Inventory System Problem

-

What is an RFID inventory system, and how does it work?

An RFID inventory system is a type of inventory management system that uses radio frequency identification (RFID) technology to track and manage inventory. RFID tags are attached to inventory items, and RFID readers are used to scanning those tags and collect data about each item’s location, movement, and status.

-

What types of businesses or industries can benefit from using RFID inventory systems?

RFID inventory systems can benefit many businesses and industries, including retail, manufacturing, logistics, healthcare, and government.

-

What are the key components of an RFID inventory system, and how do they work together?

The key components of an RFID inventory system include RFID tags, RFID readers, middleware software, and a database or inventory management system. The tags are attached to inventory items, the readers scan the tags and collect data, the middleware software processes the data, and the database or inventory management system stores and manages the data.

-

How can RFID inventory systems improve inventory accuracy and reduce errors?

RFID inventory systems can improve accuracy and reduce errors by providing real-time inventory levels, locations, and movement data. This allows for greater visibility and control over inventory, reducing the risk of stockouts, overstocking, and errors caused by manual data entry.

-

How can RFID inventory systems be integrated with other inventory management systems, such as barcoding or GPS tracking?

RFID inventory systems can be integrated with other inventory management systems using middleware software that can translate RFID data into formats compatible with other systems. This allows for greater data sharing and analysis across different inventory management systems.

-

What are some common methods for tagging inventory items with RFID tags?

Common methods for tagging inventory items with RFID tags include attaching the tags to the items using adhesive or cable ties, embedding the tags into the items during manufacturing, or using specialized tags that can be inserted into containers or pallets.

-

How can RFID inventory systems be customized to meet the specific needs of a particular application or industry?

RFID inventory systems can be customized using specialized tags, software, and hardware for specific applications or industries. This allows for greater flexibility and adaptability to meet different businesses’ or industries’ unique needs.