For most electronic tags, metal and liquid environments are quite a challenge. However, with the development of Internet technology, this problem has long been solved. The popularity of metal tags and RFID anti metal tags has brought a new beginning. It has dramatically facilitated companies with many metal assets.

What is A Metal Tag?

A metal tag use a special anti-metal, electromagnetic shielding material, and an electronic tag package.

It has the characteristics of anti-metal interference, anti-conflict, and anti-collision. It is a perfect solution from the technical level of the electronic tag can not be attached to the metal surface use of the problem.

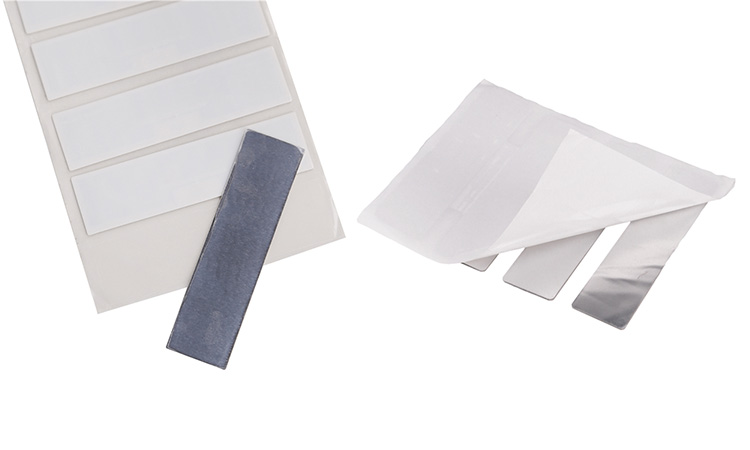

Positive Aluminum Labels

Bright colors are the hallmark of aluminum labels. Companies can freely combine among its eleven colors. The rich visual effect helps to attract consumers’ attention and enhance brand awareness.

Compared with other metal labels, it is very light. It has an anodized coating on its surface and is scratch and chemical-resistant.

Stainless Steel Labels

Labels made of stainless steel are usually the most durable. It has good corrosion resistance and high hardness.

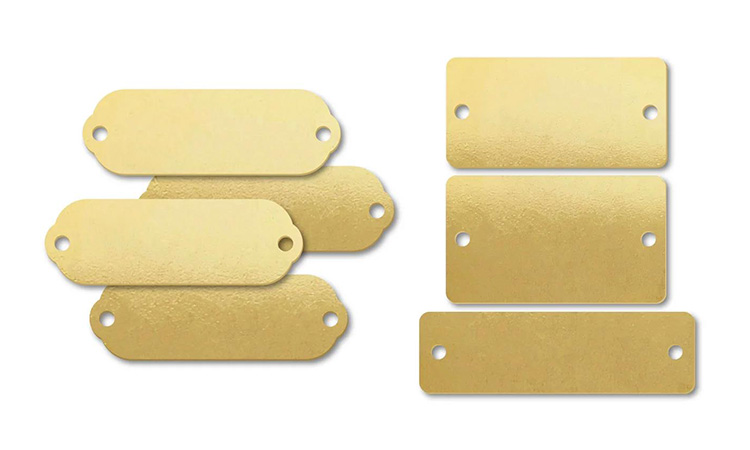

Brass Labels

Brass labels have a classic look and corrosion resistance. Companies seeking a classic look choose to use it. It is very suitable for coastal environments because salt water is challenging to affect.

- Durable

Companies can use metal tags for a long time. They generally last from a few years to a few decades; some can even last over 100 years.

Metal tags are especially suitable for harsh environments. They are made of corrosion-resistant and durable materials so they can live in harsh environments for a long time.

- High-security factor

As long as the data etch on the surface of the permanent metal tag, most means cannot make a difference. It is beneficial for companies with high-value items to protect their assets.

The company can use it to inspect the information. Each inspector carries a unique tagging tool at the site where the information inspect. The inspector adds a new date to the old label, leaving an obvious and not easily tampered with inspection records. Of course, replacing the old label with a new one would be relatively easy.

- Metal Tags Custom

Most companies can customize metal labels. It is available in many different colors and styles. Companies can customize the ideal label to suit their needs. It allows you to add logos, text and other information to it.

- Unable to tamper

A disadvantage is that operators cannot change the data printed on the label. Because assuming that the data you print on it is incorrect, you must discard it. Then make a new label again.

- Challenging to assign a specific ID number at the time of production

It usually takes 2-3 weeks to complete the production of a metal label with a series of serial numbers. Assuming you need to adjust these numbers at production, this may not be possible for a while.

- Equipment limitations

Labels made of metal are pretty tough. It is only suitable for equipment with a flat surface. For some equipment with uneven and irregular surfaces, these irregularities can limit its use.

What is an RFID Anti Metal Tag?

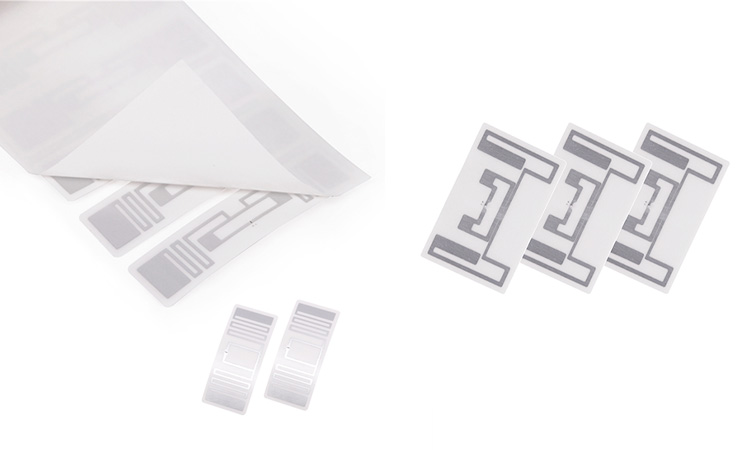

Ordinary RFID labels will be interfered with by metal during the working process, which will cause them to fail to operate normally. Radio waves emitted by RFID labels cannot penetrate the metal’s defenses and reflect.

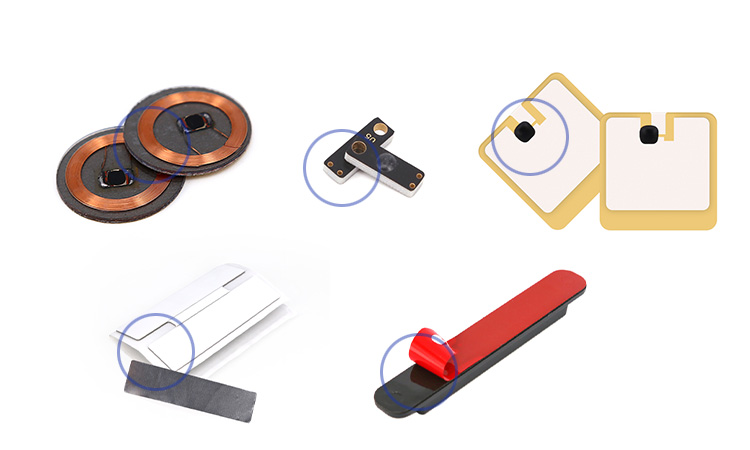

RFID metal-resistant tags are different from ordinary tags in that they allow the transponder to embed in metal. It reduces the interference caused by metal by embedding a unique material between the tag and its adhesive backing. It is not only metal resistant and high-temperature resistant, but it also has strong chemical resistance. They are lightweight and easy to attach to objects. They are also less expensive to manufacture and can be printed with different designs. Most companies use UHF passive RFID anti metal tags.

ABS anti-metal label uses ABS engineering to plastic wrap the whole label. It is sun-proof, waterproof, and high temperature resistant. It can withstand tons of pressure and is resistant to chemical contamination.

It is suitable for the oil, gas, and automotive industries. It is currently on the market for recycling-based logistics and container tracking applications.

The surface layer of the PBC metal-resistant tag allows for silkscreening or coding. It has an adhesive backing and can be attached directly to the surface of the metal.

It is impact resistant and has high corrosion resistance. The company can fix it in various ways, such as screws, rivets, strong adhesives, etc. PBC metal-resistant tags are simple and inexpensive. Therefore, it is favored by many companies.

Flexible metal-resistant tags are generally available in printable and non-printable versions.

Non-printable labels are designed with a metal-resistant antenna. It is softer than usual anti-metal labels. It can be attached to metal objects with a large arc. It is more suitable for warehousing, metal equipment, and logistics management.

Printable labels are bendable and have good metal resistance. It is especially preferred by hazardous materials management and traffic control industries.

Ceramic metal-resistant tags make of unique ceramic material. Thus, it can withstand high temperatures of thousands of degrees. It has relatively stable chemical properties. Its size is minimal, even less than 20 mm. It is very resistant to corrosion and can mount on the surface of metal objects. It is preferred by companies in most applications where high temperatures are required.

However, it also has many disadvantages. In terms of cost, it is much more expensive than PCB. During the firing process, it isn’t easy to maintain consistency and often requires manual adjustment. The different use environments make it work performance will produce significant changes.

The magnet class anti-metal label uses an extremely special anti-magnetic absorbing material package. It has anti-collision, acid, and alkali resistant and waterproof characteristics. It also has a magnet adsorption metal function.

Companies can choose metal-resistant RFID tags according to their product characteristics. Of course, if you feel that the cost budget required for these is too high, there are other options available.

Assuming you want to use RFID tags on metal, do not follow the previous method of placing them directly on the item. Because metal will interfere with RFID, it cannot penetrate metal. The moment the radio wave meets the metal, it will bounce back. Even if it barely works, it is not so good can be read. However, it is not impossible to solve this problem.

Embedding method

RFID tags can be embedded into metal objects during manufacturing. It gets additional protection by epoxy sealing. People will mainly use it in healthcare and another small tool, tracking.

Fixation method

Complex tagging gives a variety of possibilities for fixing RFID tags to metal surfaces. For example, it can be fixed to a metal surface by welding to achieve long-lasting use. It can also be fixed directly to a metal surface with screws, popular rivets, or industrial adhesives.

Encapsulated Labels

Labels for Metal Surfaces – Encapsulated Labels. It is strong, durable, and reusable.

It differs from ordinary tags. It has a tag antenna that does not come into direct contact with the metal object. It is usually attached off-angle to the metal surface. Of course, this deviation angle has been specially calculated. In this case, the encapsulated tag can receive the signal from the reader and the reflected signal from the metal.

It performs well on metal. If used on other material surfaces, it may not work as well. In some cases, the read range of encapsulated tags can also read farther than the standard distance.

In most cases, active and semi-passive RFID tags encapsulate. They can insulate from the surface of any item. In general, metal reflects radio waves causing interference to RFID tags. But passive and active RFID tags are reflective and signal to bend, providing stronger signals. They can work very stably in a metallic environment. However, they are costly and generally used in high-value physical assets.

Tracking Surgical Instruments

Initially, most healthcare organizations used only simple technologies to track their medical devices. These simple technologies included instrument count sheets, etc.

This approach only served to protect high-budget equipment and parts of the infrastructure at the time. Loss of equipment and incomplete surgical tools occur every year.

Today, the advent of technologies with advanced tracking capabilities, such as barcodes and RFID. They usher in a new beginning for the healthcare industry.

Since surgical tools and instruments often need to be repeatedly sterilized and cleaned. It is necessary for the tags attached to them to be heat resistant. Ordinary tags are certainly not up to the task. Perhaps only metal-resistant tags can. Some metal-resistant labels can embed in the tool. Even if the tool is in a high-temperature environment, the label will not produce any changes.

People can use two metal tags in conjunction with each other. Active RFID metals use on instruments. It can indicate the health care provider’s location and ownership of the instrument. Hospitals can use passive RFID-resistant metal tags in instrument assembly and sterilization.

Readers typically scan surgical instruments with passive RFID-resistant tags. The data obtained from the reader scan is uploaded directly to the hospital asset management system. The pads and trays with active RFID-resistant tags on the instruments serve to locate the instruments.

The Entire Vehicle Production Process

Dior’s Neckarsulm plant deploys RFID technology throughout the vehicle’s production process. They attach an RFID anti-metal label to the right rear of the body and retain it at all times.

The tag contains a unique ID number as well as critical vehicle information. This essential information contains the vehicle’s body design, paint job, etc. It ensures that the configuration remains consistent for every vehicle on the line.

In addition to using RFID technology in the body, paint shop, and assembly line, the factory will also use it in other non-production areas.

In logistics, people can use RFID metal tags to locate and identify vehicles, ensuring that each new owner has their own unique Audi vehicle. Employees will use drones to test the RFID tag’s location function and collect all relevant data to enhance that capability.

According to the above understanding, I believe you already understand metal tags and RFID anti metal tags. For the use of different tags, the environment in which the product is produced may cause its performance to vary. Companies can first learn about the products they are interested in ahead of time. Then test whether the labels are suitable for their products. Then finally, the order in large quantities.

-

What are meta tags, and how are they used?

Metal tags are durable identification and tracking devices made from metal. They are commonly used in industrial and commercial applications to identify and track products, equipment, and assets.

-

What are the benefits of using metal tags in industrial and commercial applications?

Metal tags offer several benefits, including durability, resistance to environmental factors, long lifespan, and customizable design options.

-

What types of metals are commonly used to make metal tags?

Common metals used for metal tags include aluminum, stainless steel, brass, and copper. The choice of metal depends on the intended application and environmental factors.

-

How do metal tags compare to other types of identification and tracking systems, such as barcodes and RFID?

Metal tags offer greater durability and resistance to environmental factors than other tracking systems and can be customized with specific information. However, RFID may not offer the same automation and real-time tracking capabilities.

-

What are some common methods for attaching metal tags to objects or equipment?

Common methods for attaching metal tags include welding, adhesive bonding, screws, rivets, or tie-wraps.