RFID is one of the most promising technologies in textile and apparel. Most enterprises will use RFID clothing tags for clothing manufacturing, logistics distribution, inventory management, etc. Since its launch, companies such as CVS, Prada, and Walmart have implemented the technology. They also explored the impact of the technology on their business. RFID occupies a significant position in the apparel industry.

What does RFID Mean on a Clothing Tag?

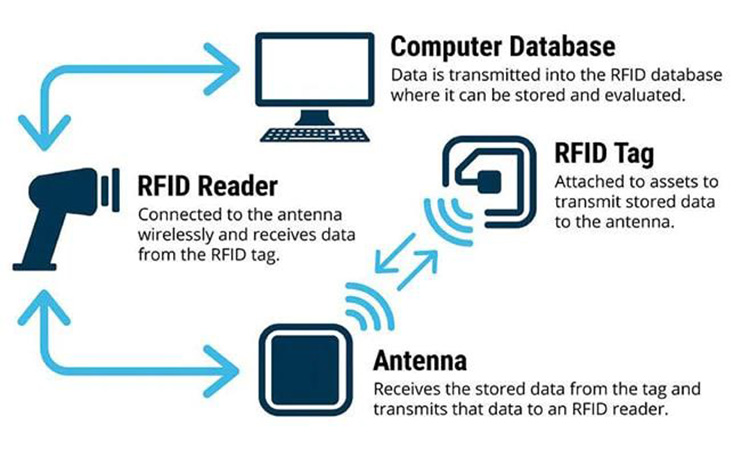

RFID stands for Radio Frequency Identification. Regarding clothing, RFID technology is often used in the form of RFID tags or labels attached to garments. These tags contain a small chip and antenna that can be read by an RFID reader, typically located at a store or warehouse. When scanned, the tag can provide information about the garment, such as its size, color, style, and price. RFID technology can help retailers manage their inventory more efficiently and accurately and improve customer service by ensuring that popular items are always in stock.

RFID technology is used in various industries to track and manage inventory, including clothing retail. RFID tags are small electronic devices that can be attached to clothing items, and they use radio waves to communicate information wirelessly to a reader.

Here’s how clothing RFID tags work:

- RFID tags are attached to clothing items during the manufacturing process. These tags contain a microchip and a tiny antenna that can communicate with a reader.

- When a reader is within range, the RFID tag emits a radio signal that contains information about the item, such as the brand, size, color, and price.

- The reader captures the radio signal and converts it into data that can be sent to a computer or inventory management system.

- The data from the RFID tag is used to update inventory records and track the movement of clothing items within a store or warehouse.

RFID technology can also help prevent theft by alerting store personnel when a tagged item is removed from the store without being purchased.

RFID tags are electronic devices that automatically identify and track objects using radio waves. This technology has several benefits, including saving time, effort, and money. RFID tags allow data about objects to be collected and entered directly into computer systems without much human intervention. This can streamline many business processes, from manufacturing to sales.

For example, RFID tags can help reduce the time and effort required for inventory management. Rather than manually counting and tracking items, RFID tags can automatically identify and track them as they move through the supply chain. This can save time and reduce the risk of errors in tracking inventory.

In addition to inventory management, RFID tags can help streamline other processes, such as shipping and sales. RFID tags can help reduce the time and effort required to process orders and shipments by automatically identifying and tracking items. This can help businesses operate more efficiently and save money.

RFID vs Barcode: Which is Better in Clothing?

Barcodes have been around the world for a long time, and I’m sure many of you know that they have some drawbacks regarding product and identification.

For example, barcodes can only identify and track one product at a time and must be done linearly. It means that it takes more time when used to track and identify large quantities of clothing.

RFID requires less time to complete the task than barcodes. It does not require a straight line of sight and can track multiple products simultaneously.

RFID technology is more cost-effective than barcode technology. It gives businesses a better working experience. There are more distinct differences between them:

- Key differences 1: durability

- Unlike barcodes, which need to be attached to the product, RFID labels can embed in the product. It is impervious to harsh conditions such as dirt and mess. RFID can be used in most environments. You can use them for a more extended period. It saves you the cost of repair and replacement tags.

- Key differences 2: Wider reading range

- RFID labels can generally be divided into active and passive tags. The reader can read Passive RFID tags one meter away. It can easily read Active RFID tags even at 100 meters. Barcodes are better; Conversely, readers can only read them nearby.

- Key differences 3: More memory

- RFID tags have dynamic storage space. It can store more content.

- Key differences 4: Read/Write Functionality

- RFID systems provide read and write capabilities. You can use the reader to modify the data stored in it at any time. A barcode is an opposite. The reader can only read it after it has been printed and cannot be modified.

This table comparing RFID and barcode technology for clothing:

| Technology | RFID | Barcode |

|---|---|---|

| Type of Data Stored | RFID tags can store more data than barcodes, including unique identification numbers, item descriptions, and even manufacturing and shipping data. | Barcodes can store limited data, typically just a product number that must be cross-referenced with a database to obtain additional information. |

| Read Range | RFID tags can be read from a distance of several feet, allowing for rapid and accurate tracking of multiple items at once. | Barcodes must be scanned at close range, which can be time-consuming and require more manual labor. |

| Durability | RFID tags are generally more durable than barcodes and can withstand harsh environments, including exposure to water, heat, and cold. | Barcodes can be damaged or faded over time, making them difficult or impossible to scan. |

| Cost | RFID tags are typically more expensive than barcodes, both in terms of the cost of the tags themselves and the infrastructure required to read and manage them. | Barcodes are relatively inexpensive, requiring only a barcode scanner and a database to manage the information. |

| Applications | RFID tags are well-suited for high-volume, high-value items, such as designer clothing or luxury goods, where accurate tracking and theft prevention are critical. | Barcodes are more commonly used in low-cost, low-volume applications, such as basic clothing items or accessories. |

For companies with different needs, it is difficult for them to distinguish between winners and losers. In most cases, RFID can easily replace barcodes. Of course, barcodes may work better if they are attached to RFID clothing tags.

RFID can be used in various industries. It gives you better control over the garment production process. It allows you to save labor costs without compromising product quality. It also increases your profits. Of course, it has the following advantages.

Suitable Means of Inventory Control

As we all know, managing a garment factory is an exceptionally troublesome task. The number, as well as the type it needs to supervise, is enormous. And it is easy to have various problems in the process of supervision.

Using management technology can help companies solve the problem of supervision. RFID clothing tags can help you track specific items’ locations and inventory levels in real-time. It gives you a good idea of the number of goods, sales, etc. It helps operators to adjust their operational strategies better.

Counterfeit goods are everywhere, and it is the target of countless merchants. Your clothes often hit the market, and counterfeits come along with them. Consumers can’t tell the difference between real and fake. They are easily duped and faced with this situation without reasonable means. Both you and the consumer will suffer significant losses.

You can employ RFID tags to curb the threat of counterfeit goods. Companies can achieve this effect by embedding RFID tags in producing clothes. The RFID tag stores a unique ID number as well as product information. Merchants who receive the product can scan the tag with an RFID reader to verify the authenticity.

Low Operating Costs

RFID can effectively reduce a company’s need for human resources. It allows multiple products to be scanned simultaneously without requiring manual real-time monitoring. The inventory quantities obtained using it can be 100 percent correct. Only some situations, such as metals, and liquids, can interfere with its accuracy.

RFID tags are usually durable. Active and passive RFID tags can last 3-5 years. Passive RFID tags are inexpensive and are the preferred choice for most retail industries.

Companies can get reliable inventory information quickly with an RFID system. Generally, as long as the RFID system continues to operate, you can obtain the latest data in real time. The data scanned by RFID readers is uploaded to the asset management system via the Internet. Operators can quickly handle the situation by viewing the information in the database. You will get information about raw materials, finished goods inventory, and supply chain.

Tracking samples is an effective way to avoid prototype theft. Before a product sale, samples are sent by mail to significant manufacturers. Various incidents may happen during the shipping process. In the event of loss or theft, your company could suffer significant property damage. Therefore, you must reliably track your samples.

RFID technology is one of the ideal ways to achieve tracking of merchandise. Companies can track their merchandise by using RFID tags embedded in them. You can quickly get sample routing information. This information includes information on all places on the way from departure to arrival. It helps you to reduce sample loss and merchandise loss rate.

RFID clothing tags are not easily copied. The RFID chip inside it has an ID number. This ID number is unique and cannot be easily copied. This feature allows you to avoid data leakage and other recording errors.

It also has a large and sophisticated data encryption system. It is challenging to do if a hacker tries to steal your information. It effectively prevents unauthorized individuals from accessing the system data.

Most RFID tags for clothing also have anti-theft features. By tagging clothing items with RFID chips, retailers can track the movement of items throughout their stores and identify potential security risks. They will close the communication channel immediately after the reader reads the data. Additionally, RFID-enabled security systems can help retailers identify and deter potential shoplifters. Individuals who enter the channel without permission will trigger the alarm system. The operator will receive the news as soon as possible.

Related Articles: Basics of Electronic Article Surveillance (EAS) Systems

High-cost budget. While there are many benefits to adopting RFID technology in the apparel industry, that doesn’t mean it doesn’t have its drawbacks. It would be best if you won these challenges to get the best results.

RFID systems require higher cost budgets than barcode systems. Of course, this budget depends on your future usage and compatibility with existing systems. Before deciding to upgrade or create a system, you need to evaluate it to ensure that you can get a significant return on your investment.

Compatibility with existing infrastructure. Usually, you may need to spend more cost and time if they are not compatible. However, since the technology is long-term, you will benefit significantly by ignoring this factor.

The interference factor. RFID systems transmit data via radio waves. So, it may be more susceptible to metal, liquid, and other gadget environmental interference. You need to check the existing operating environment to eliminate interference. The ideal work environment to realize the full potential of RFID.

The benefits of RFID technology in the apparel industry outweigh the drawbacks. As a result, many companies have adopted it.

Using RFID to Manage Clothes

An Australian-based company, has launched an intelligent laundry basket. The laundry basket is developed using RFID technology. Each piece of clothing has an RFID tag stuck to it. The tag is made of silicone sleeve material, which is waterproof, anti-allergic, etc. It is a passive RFID tag. It is mainly used to identify and store washing program data.

RFID tags are used in conjunction with RFID readers. The laundry basket that collects dirty clothes is equipped with an RFID reader. It scans when you place the already dirty clothes into the laundry basket. The data information from the RFID tag is collected and uploaded to the corresponding application.

You can access information about your laundry rights in the app. Your smartphone can generally download the app. However, both need to be connected to the Internet simultaneously to communicate. You can see on your smartphone what clothes are in the laundry basket, how to wash them, etc.

You can manage the clothes uploaded via the application on your smartphone. It lets you find what you’re looking for without rummaging through dirty laundry.

The following video introduces soft silicone laundry tags for apparel store management, tracking and identification:

Enhancing the Customer Experience

In 2012 Burberry implemented RFID technology in some of its flagship stores. It enhances staff control over clothing quality and inventory by using RFID tags.

It also enhances the experience of customers visiting the store to purchase items. When customers take the clothes they want to try on to the dressing room, the mirror in the dressing room will show a different picture. The RFID tag will activate the mirror and show a video about the clothes. The video mainly tells about this dress’s production and production process, as well as its style in the fashion show. It gives the customer a deeper understanding of the particular piece of clothing they want to buy.

The famous German department store “Galeria Kaufhof in Essen” also uses RFID technology in its fitting rooms. It uses a smart mirror in the fitting room to advise customers on what to buy. The intelligent mirrors are embedded with RFID readers. When a customer goes to the fitting room to try on a suit, the smart mirror automatically makes the appropriate purchase suggestions. These suggestions include matching accessories, suit fit, etc. It is also used in conjunction with the “smart rack.” It gives the customer a choice of styles and sizes.

Brand Segregation

Many department stores with many brands on the market use RFID apparel tags for brand segregation. RFID can effectively track the inventory and location of different brands and different series of clothes in the store. It has a meager chance of human error compared to bar codes. It is because there is very little dependence on people to monitor inventory levels and brand identification using it.

RFID tags are typically designed to be difficult to remove from clothing. Doing so without proper tools or techniques could damage the garment or the tag itself.

If you have an RFID tag on your clothing that you need to remove, there are a few options available to you. The best option is to take it to the store where you purchased it. Alternatively, you could take it to a professional tailor or dry cleaner who can remove it safely. They will have the appropriate tools and techniques to remove the tag without damaging the garment or the tag.

You must note that removing an RFID tag without permission or for illegitimate purposes could be illegal and could result in legal consequences. It’s always best to seek permission or professional assistance if you need to remove an RFID tag from your clothing.

The cost of implementing RFID clothing tags can vary depending on the size and complexity of the system. However, RFID technology is generally more expensive than traditional barcode systems. The prices of RFID tags for clothing can range from a few cents to several dollars per tag.

For instance, a basic adhesive RFID label tag can cost around 10 to 30 cents per tag, while a more advanced RFID woven label or hang tag can cost between 50 cents to a few dollars per tag. The cost per tag may reduce with a larger order quantity.

It’s important to note that the price of RFID tags may also vary depending on the technology used in the tag. Such as HF (high frequency) or UHF (ultra-high frequency), and any additional features or customization options. Additionally, some suppliers may offer bulk discounts or price breaks for larger orders.

If you’re planning to buy RFID clothing tags, conducting thorough research and comparing prices from various suppliers is recommended to find the most suitable option that fits your budget and requirements.

RFID technology has a significant role to play in the apparel industry. Companies can find a breakthrough point by considering updating their existing technology. RFID can be used to transform existing supply chains and related processes in retail. They can make companies more competitive.

Related Contents:

- What is RFID Labels and What Does It Consist Of?

- RFID Inventory System: What are Its Pros and Cons?

- Top 9 Benefits of Food RFID

-

What clothing companies use RFID tags?

Many clothing companies use RFID tags, including major retailers such as Zara, H&M, Macy’s, and Levi’s. RFID technology is widely used in the fashion industry to track inventory, prevent theft, and improve supply chain management.

-

How is RFID used in clothing?

RFID is used in clothing in several ways. One common use is inventory management, where RFID tags are attached to clothing items and scanned to track their movement from the manufacturer to the store. RFID can also be used for anti-theft purposes, where tags are attached to high-value items and monitored to prevent shoplifting.

-

How does H&M use RFID tags?

H&M uses RFID tags in its stores to improve inventory accuracy, reduce out-of-stock items, and improve the customer shopping experience. RFID tags are attached to every item of clothing, and when a customer tries on an item, it is automatically detected and updated in the inventory system. This allows H&M to replenish popular items quickly and ensure customers can find the sizes they need.

-

Does RFID stop shoplifting?

While RFID can be used as an anti-theft measure to deter shoplifting, it does not completely stop it. RFID tags can be removed or deactivated by determined shoplifters, and some types of RFID tags can be read from a distance, making them vulnerable to hacking. However, when combined with other security measures, such as security cameras and store personnel, RFID can effectively reduce theft and improve inventory management.