Using RFID labels can be a great convenience for you. Most merchants may choose to customize RFID tags directly. And large purchases are generally not used up in their entirety. Discarding or piling new RFID tags results in waste and unnecessary property damage. For these remaining RFID tags, you can program them yourself. RFID programming is easy. You can learn more about RFID programming and the various benefits of RFID in this article.

About RFID

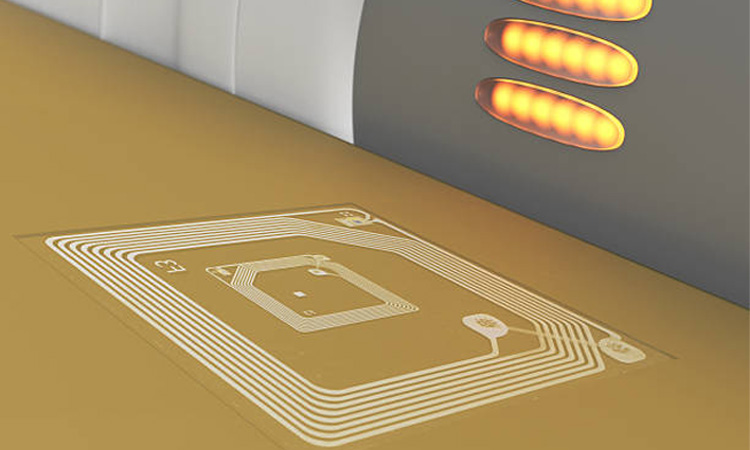

Before attempting to program an RFID system, it is important to understand the basics of RFID technology. RFID tags are composed of three components: microchip, antenna, and substrate. Each component performs its duties and plays an important role in RFID tags. The microchip is the leader, the antenna is the signaler, and the substrate is a different group member. They form a department.

They cooperate. When the antenna receives the radio wave from the RFID reader, it is immediately passed to the RFID chip. On the other hand, the substrate keeps the antenna connected to the chip while providing the foundation for the RFID tag. When the chip is powered on, the antenna also sends information to the RFID reader. It receives the information from the same antenna and displays it for the holder to see. It needs to be programmed with a specific application.

We can purchase RFID tags that the manufacturer has mass-produced and programmed. When the amount used is less than purchased, we can reprogram the RFID. We can also buy new blank RFID tags. Program the RFID directly using the app to make it the way you want. We need to be aware of some things before we program the RFID. For example, RFID chip storage information, character limit, and memory format.

Information You Need to Know in Advance for RFID Programming

What is RFID Tag Programming?

RFID programming is the process of installing a radio frequency identification (RFID) tag on a product. The tags track the movement of this product and provide a means of providing information that businesses can use to improve their efficiency.

Programming your RFID tags involves working with an RFID programmer, a device that allows you to encode data into your specific codes. This process will help ensure that each item you produce has the right information stored in its tag and can be traced back to the production line where it was made.

Understanding RFID Tag Data Information

The first step in learning how to program RFID stickers or cards is understanding their use and why. RFID cards are smaller than traditional credit cards and have a chip inside them that contains information about the person who owns them. These chips contain contactless ID numbers that allow you to identify individuals with an RFID reader when they enter a facility.

Before programming RFID, you also need to know the data information of the RFID tag in advance. For example, you need to know where the data is stored, the language options, and the length of the data. Of these, only the EPC and user memory banks support reprogramming. Usually, people program in the EPC memory bank. EPC is the default storage area for RFID readers to read.

You need to confirm the form in which the data will appear inside the RFID tag. Most people use the two basic numbering systems, Hexadecimal (Hex) and ASCII. It is because they are the simplest. They are both expressed using numbers and letters. Hex, in particular, consists of the numbers 0 – 9 and the letters A – F. When programming RFID, you only need to know which characters you can use or can not. In the reader software, it is also extremely easy to operate. You can use toggle switches and checkboxes to indicate your numbering system.

You need to know the EPC memory of the RFID tag you are purchasing. Once you know its memory information, you can calculate how many characters it can hold. With Hex, divide the number by 4. With ASCII, divide by 8. The total number of characters you can encode into the tag is the answer. Usually, RFID tags have 96 bits of EPC memory. Based on this number, it can hold up to 24 Hex characters or 12 ASCII characters.

What Programming Language is Used in RFID?

While various programming languages can be used to develop applications that interact with RFID technology, there isn’t a specific programming language used exclusively for RFID.

When developing software that interacts with RFID readers and tags, developers can choose from various programming languages, such as Java, C++, Python, and others. The selection of a programming language depends on the specific application and hardware components being used. While Java, C++, and Python are commonly used for this purpose, the choice of programming language ultimately depends on the application requirements and the compatibility with the hardware and software components used.

Hardware and Software Needed for RFID Programming

Hardware Needed for RFID Programming

RFID hardware usually consists of a printer that can encode data, a reader, and an antenna. There are many choices of printers on the market. Generally, you can choose from high-performance desktop or mobile models. RFID readers can be either fixed or handheld. Choose which one to choose depends on the application you will be using. Readers allow you to understand your operation faster. The antenna is the important component that allows the reader to read the tags. It is the hub that connects the RFID tags. It also acts as a conduit for moving data. The antenna enables communication while allowing the organization to capture information. It can deliver and manage data information.

Software Needed for RFID Programming

Usually, RFID software and RFID hardware are used in conjunction. They complement each other. RFID software helps you get and use the information. It includes firmware, application software, and middleware. Firmware is the software in the RFID hardware itself, which is responsible for running the device. Application software collects data information using RFID for specific business needs. It can be anything. Middleware, on the other hand, is the tool between the firmware and the application. It is the communication hub between the RFID component and the application. It collects your raw data and shares it as a tool with the application software. It is an essential tool.

How to RFID Programming?

RFID programming is the process of getting an RFID tag (or chip) to do what you want it to do. It’s also called “tag writing.”

If you want your RFID chip to read and write data, but not move on its own, you’ll need to program it first. If you want it to move on its own, you’ll need to program it again.

You’ll need an RFID programming card (or sticker) to program an RFID chip. These are available online from most retailers who sell RFID cards and stickers.

These RFID tag also contains a specific ID and other information that may be present. In general, active RFID tags are much easier to read and program. On the other han, passive RFID tags must be within a few feet of a reader at all times to work. It is because there is no power source inside it, and only a small amount of energy is generated when it is close to the reader. This energy supports the tag’s ability to transmit its unique ID.

The key to RFID chip programming is to use a unique tag ID in the application, which is a symbol of its identity and distinguishes it from other tags. Suppose you want to use it for inventory management. You must place the RFID tag on the item and then associate the two using the unique ID. Finally, set a unique key for each item. This unique key allows access to the specified RFID tag.

Programmable RFID Stickers are used to track inventory items such as pallets, crates, or boxes. You can use these stickers on pallets or boxes by simply sticking them on the surface of the object you want to track. The sticker will contain information about the type of object, its size, and weight, along with other details like serial number, etc., so that the system will recognize it when scanned at a checkout counter.

If you can program it, the bank card label can be used as a membership card. Its operation is very simple. It would be best if you did a simple operation before sending it to members. First, add the field in the membership database for the specified tag ID. You must scan the card and associate this unique tag ID with the designated member. A unique tag ID is obtained by scanning the card. Enter the ID into your member database to get information about that member.

RFID Programming Step-by-Step Tutorials

To program RFID tags, you have multiple options when it comes to hardware and software. Listed below are the steps to program an RFID tag using a combination of both hardware and software methods. For this example, we will use an RFID tag with a 96-bit EPC Memory Bank and hexadecimal encoding (0-9, A-F). There is no need to toggle the ASCII switch in the software. The EPC Memory Bank has 96 bits, allowing for encoding up to 24 characters using 4 bits for each hexadecimal character.

Combination 1: ThingMagic USB Pro Reader + ThingMagic URA Software

If you’re using the ThingMagic USB Pro Reader with the ThingMagic URA software to program RFID tags, follow the steps below:

- Download and open the ThingMagic URA software on your computer.

- Connect your ThingMagic USB Pro RFID Reader to your computer via USB.

- Click “Refresh” in the software to detect your USB reader, and click “Next.”

- Select your region of operation. For example, if you’re in North America, choose “NA” and click “Next.”

- Click “Connect” to establish a connection with the reader.

- In the tab that appears at the top, double-click on “Write EPC”.

- Select Hexadecimal encoding as the default setting.

- Click “Read” in the “Current EPC” box to read the current EPC of the tag.

- Type the new EPC in the “New EPC” box.

- Click “Write” to program the new EPC onto the tag.

Please note that the software provides several options for encoding. However, for this example, we will use hexadecimal encoding, the default setting in the software.

Combination 2: ThingMagic USB Pro Reader + Vulcan RFID Read & Write Software

If you’re using the ThingMagic USB Pro Reader with the Vulcan RFID Read & Write software to program RFID tags, follow the steps below:

- Download and install the Vulcan Read & Write software on your computer.

- Connect your ThingMagic USB Pro RFID Reader to your computer using a USB cable.

- Open the Vulcan Read & Write software.

- Select “ThingMagic (Jadak)” from the manufacturer dropdown menu.

- Select “Serial” from the connection dropdown menu.

- Click the “Scan Available Ports” button to locate the USB reader’s port.

- The port information will appear in the white box to the button’s right. Enter this information into the top box above.

- Click “Connect to Reader.” Then wait for it to establish a connection with the reader.

- Click “Read” to display the current EPC data.

- Enter the new EPC data in the white box that appears next to the “Write” position.

- Click “Write” to program the new EPC onto the tag.

Please note that the Vulcan RFID Read & Write software provides several options for programming RFID tags, including quickly programming passive RFID tags via the Excel Spreadsheet functionality.

Significant Improvements in Work Efficiency

RFID offers a reliable benefit in automating production processes. It eliminates the need for humans to monitor the monitoring system in real-time. Just set up a specific program, and it will run continuously. It gives employees more time to focus on other, more important tasks. It is more advanced than barcodes. RFID readers can read RFID tags on multiple items at once. Using RFID tags reduces labor costs and shortens delivery dates.

Reduce Unnecessary Asset / Inventory Loss

RFID can keep track of your physical assets / inventory. Assets are critical to every business. An expensive piece of equipment that is suddenly lost can cause unnecessary property damage to a business. It can cause panic among employees, fearing that they will be reduced in pay or even fired if they can’t find the equipment. RFID synchronizes data information to a designated database by placing. And associating RFID tags with the equipment. It installs a “location system” on the equipment. If a business has real-time access to physical assets/on-hand inventory information, then there is no need to worry about losing things. RFID provides a simple and inexpensive way to track your assets.

Providing Real-Time Product Data

RFID can adapt to various harsh environments and provide real-time data related to products. It is more durable than barcodes. It can withstand a variety of harsh environments. For example, high temperatures, high humidity, chemicals, and extremely rough handling environments. It collects data automatically. It tracks and provides real-time data, whether a large physical asset inventory, a single product lot, or a particular product. Having real-time inventory and product location data is easy in any environment.

Benefits of RFID in Retail Locations

Makes Checkout Faster

One of the reasons why offline stores often complain is that the checkout queue takes a long time. People generally choose to buy goods online when they are not in urgent need of use. There is no need to wait in line for manual checkout when purchasing goods online, and you can pay as you go. Therefore, it is crucial to improve the speed of the in-store checkout process. It can greatly improve customer satisfaction. Using RFID at the checkout can greatly speed up the transaction time. It can be up to 75 percent faster. It also gives employees more time to process online orders and pickups. It allows employees to reduce their workload and provide better service to customers.

Making Self-Checkout Easier

Self-checking products using RFID tags takes less time than traditional acoustic magnetic (AM). RFID-enabled self-checkout makes purchasing merchandise more convenient. It eliminates the need for customers to place items one by one individually on the scanner. The customer places a basket full of items on the self-checkout counter. The scanner will identify the items in the basket individually at the same time. It takes only a few seconds to scan and display the product data. It reduces checkout time by more than half. It reduces the risk of customers forgetting to scan items and taking them out of the store.

Make Return Fraud Impossible

Returns themselves are a common occurrence, but there will always be criminals who use them for improper gain. Money obtained from shoplifting and returning to the shop with worn-out merchandise is an undue advantage. They are returns fraud. If this behavior occurs frequently, it will cause huge losses to the store. The use of RFID can prevent such fraud. It can detect whether the returned item has been purchased before. It also lets merchants know through which channel purchased the item. The product may be involved in return fraud if no information can founding. It makes it impossible for criminals to gain any benefit through this route.

There are many benefits to using RFID. You can buy blank RFID tags and readers online or offline. You can program RFID to perform your desired functions by downloading specific applications. Of course, you can customize RFID tags in large quantities if you don’t want to bother. You can program the unused tags by yourself.

About RFID Programming FAQs

-

What is RFID programming, and how is it used in RFID technology?

RFID programming involves writing software code to control and manage RFID systems. It is used to customize the behavior of RFID systems, collect data, and integrate RFID systems with other technologies.

-

What are the programming languages commonly used for RFID programming, and what are their differences?

Common programming languages used for RFID programming include C, C++, Java, and Python. Each language has its own syntax and structure, but all can be used to write RFID software code.

-

What are some common programming tasks in RFID programming, and how are they performed?

Common programming tasks in RFID programming include configuring RFID readers and tags, controlling the behavior of RFID systems, and collecting and analyzing data. These tasks are performed through writing and testing software code.

-

How can RFID programming be used to customize RFID systems for specific applications or industries?

RFID programming can be used to customize RFID systems by configuring the behavior of RFID readers and tags, designing user interfaces, and integrating RFID systems with other technologies.

-

How can RFID programming integrate RFID systems with other technologies, such as barcoding or GPS tracking?

RFID programming can integrate RFID systems with other technologies by writing code that translates data between systems and technologies. This allows for greater data sharing and analysis across different systems.

-

How can RFID programming improve data security and privacy in RFID systems?

RFID programming can improve data security and privacy in RFID systems by implementing encryption and authentication protocols, limiting access to sensitive data, and monitoring and auditing system behavior.

-

Can I program RFID with my phone?

Yes, it is possible to program RFID tags using a smartphone, provided the phone has an RFID reader or is connected to an external RFID reader. Several mobile apps also allow users to program and read RFID tags using their phones.

-

Can you write data to RFID?

Yes, it is possible to write data to RFID tags. RFID tags consist of a memory bank that can be programmed with information. This information can be accessed by an RFID reader when the tag is within range of the reader’s antenna.

-

How to program RFID with Arduino?

To program RFID with Arduino, you would need an RFID reader module compatible with Arduino, such as the MFRC522 RFID reader module. You can then use the Arduino IDE and a compatible programming language, such as C or C++, to write code that interacts with the RFID reader module to read and write data to RFID tags.

-

Can Arduino read RFID?

Yes, Arduino can read RFID tags using an RFID reader module, such as the MFRC522 RFID reader module. You can use Arduino to write code that interacts with the RFID reader module to read data from RFID tags when they are within range of the reader’s antenna.