Since the vigorous promotion and application of RFID, RFID can be seen everywhere in our lives today. RFID labels can use for inventory management, payment terminals, and offline retail. The widely known types of RFID are active RFID tags, passive RFID tags, and semi passive RFID tags. Do you know anything about them? This article focuses on the information content of passive RFID tags. Including what it is, what it is manufactured from, and what types it can be divided.

A passive RFID tag is simply an RFID tag without a battery. It is generally used in small-scale operations. It is also used in tracking system. It has no power source inside the body and is powered by the RFID reader by transmitting energy through radio waves. Compared to active RFID tags and semi-active RFID tags, it is more suitable for companies that have large-scale physical assets. The passive RFID tag is because it is relatively more cost-effective. It also has a longer lifetime.

Passive RFID tags come in several variants. The more common ones on the market are inlays and hard tags. The inlay is attached by adhesive to the physical asset that needs to be tracked. It is the most used and the cheapest. Hard passive RFID tags are made of plastic, metal, and ceramic materials, which are relatively more robust and durable. It is usually used in high temperatures, extreme weather, and outdoor environments.

Passive RFID tags can operate at different frequencies. Depending on the frequency, it offers a corresponding read range and different features.

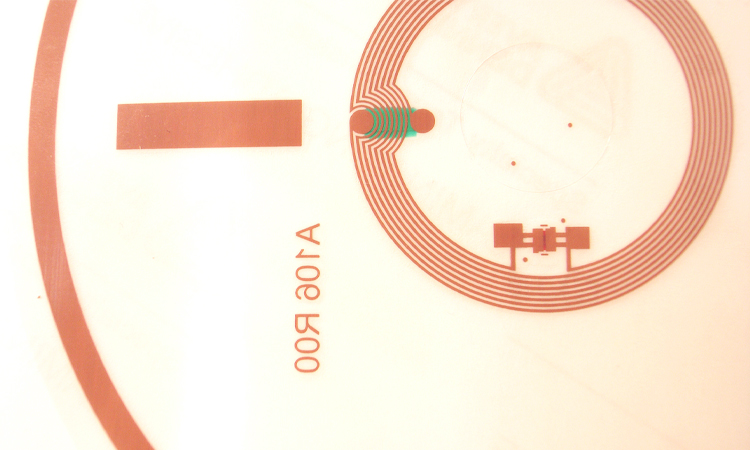

A Passive RFID tag is activated when it is exposed to an electromagnetic field, which the reader generates. The reader sends out radio waves that are picked up by the tag’s antenna. This causes the tag’s microchip to be energized, allowing it to send back data to the reader.

Passive RFID tags usually contain the microchip (integrated circuit IC) and the antenna. However, from a more comprehensive perspective, it comprises the inlay, the film that forms the tag’s body, and the tag face substrate. Usually, the tag is coated with an adhesive that can be directly adhered to the tracked physical asset. These adhesives are usually tamper-resistant. If the tag does not have an adhesive, it can be used as a hanging tag attachment. Different mechanical fasteners can also affix it.

Passive RFID tags can carry the customer’s symbolic company logos, product numbers, or other labels. The manufactured passive RFID tags can be cut and separated to meet the customer’s needs for physical shapes.

Passive RFID tags have a variety of operating frequency bands. It can be divided into three system types: low frequency (LF), high frequency (HF/NFC), and ultra-high frequency (UHF).

Low Frequency (LF) RFID

The LF frequency band is generally between 30KHz – 300KHz. A typical LF RFID system operates mainly at 125KHz or 134KHz. It offers a readable range of about 10cm, which is quite short. Its reading speed is quite slow. While its disadvantages are obvious, its advantages are equally outstanding. It is resistant to external interference. It is generally more expensive than HF and UHF RFID tags, but the cost varies depending on the type and application.

LF is typically used for animal tracking and access control applications.

Animal control and tracking system are normative standards in ISO 1422 and ISO/IEC 1800-2.

High Frequency (HF) RFID

The frequency of HF is between 3MHz – 30MHz. Typically, most would use a 13.56MHz HF RFID system. Its read range will be between 10cm – 1m. It is less resistant to interference than LF RFID systems.

HF RFID systems are typically used for ticketing, payment, and data transmission.

There are several standards for HF RFID systems. The standard for object traceability is ISO 15693. The NFC standards (Near Field Communication) are ECMA-340 and ISO/IEC 18092. The standards for smart cards are ISO/IEC 14443A and ISO/IEC 1443, and JIS X 6319-4. It is also called the MIFARE standard and is usually used in cards with payment systems.

Ultra High Frequency (UHF) RFID

The frequency of UHF is between 300MHz – 3GHz. It has a read range of more than 12m, and the data transmission speed is quite fast. It is very sensitive to interference. UHF RFID tags are easier to manufacture than the other two system types. It is also relatively less costly.

The RAIN RFID UHF system is compliant with the UHF Gen2 standard. Its use frequency is between 860MHz – 960MHz. It just satisfies the operational requirements of most regions. It has a wide range of uses. It can use in the inventory of store merchandise. It can also use in the identification of medical protection drugs. RAIN RFID UHF systems are widely used in various RFID projects.

The standard adopted by the UHF RFID system is EPC Global Gen2 (ISO 1800-63). It is a global standard.

Passive RFID tags have no power source of their own and can only get energy from the radio waves emitted by the reader. The energy obtained is very little and is only enough to power its IC. Therefore, its functionality is limited. In the low and high-frequency range of operation, a passive RFID tag uses inductive coupling. In the high-frequency range, it uses radiative coupling.

In most cases that are not in the reader area range, it does nothing without power. It will always be silent. Compared to the other two RFID tags, it is simple and cheap. It meets the needs of most people.

While both active and passive RFIDs can be used for asset tracking, they differ in terms of form factor and configuration. Here’s how they compare:

Power Source

One of the key differences between active and passive RFID tags is their power source. Active RFID tags have a power source, typically a battery, allowing them to transmit signals actively and communicate with RFID readers. On the other hand, passive RFID tags do not have a built-in power source and rely on the electromagnetic energy from the RFID reader to power the tag and transmit data.

Range

Another significant difference is the range of communication between the RFID tag and the reader. Active RFID tags have a longer range compared to passive RFID tags. They can transmit signals over greater distances, typically tens to hundreds of meters. Passive RFID tags, on the other hand, have a shorter communication range, usually within a few meters.

Cost

Cost is a factor that differentiates active and passive RFID tags. Active RFID tags, with their built-in power source and extended range, are more expensive than passive RFID tags. The cost of batteries and the additional circuitry in active tags contribute to their higher price. Passive RFID tags, which do not require a power source, are generally more cost-effective.

Size and Form Factor

Active and passive RFID tags also differ in size and form factor. Active RFID tags are typically larger and bulkier due to the inclusion of a battery and additional circuitry. Passive RFID tags, being battery-free, are smaller and more lightweight, making them suitable for applications where space and size constraints are a concern.

Read/Write Capability

Active RFID tags can both transmit and receive data. They can actively communicate with the RFID reader, enabling two-way data exchange. Passive RFID tags, on the other hand, are typically read-only and cannot send data back to the reader. They can only transmit their stored data when powered by the RFID reader’s electromagnetic field.

Environmental Suitability

The environmental suitability of active and passive RFID tags varies based on the application requirements. Active RFID tags are better suited for harsh environments, such as outdoor or rugged conditions, where long-range and robust performance are needed. Passive RFID tags, with their smaller form factor and simpler design, are generally suitable for less extreme environmental conditions.

- Long data reading range. It has 150 meters.

- A large memory space capacity can store more data.

Disadvantages

- It is more expensive than passive RFID tags.

- It has a relatively short life span.

- It is more costly to use

- It tends to cause radio noise.

- It is more cost-effective.

- It has a longer service life.

- It is small and lightweight.

- It is cheaper to order in large quantities.

- It can withstand harsh environments.

Disadvantages

- Short signal range. Only 5 meters.

- It has a very limited data storage capacity.

- Power can only obtain through the reader.

In summary, both active and passive RFID tags have advantages and disadvantages. The choice of which RFID tag to use depends on your anticipated application requirements.

Paper documents are essential in various office environments, and design firms need photos. The use of passive tags can reduce the occurrence of accidents such as lost, misplaced, and even theft of office documents. There is one checkpoint – an RFID scanner at the entrance and exit of each building. The RFID scanner can read the RFID tag on any document. The system automatically alerts you if someone enters or leaves the office with an unapproved document. Passive RFID tags are effective in preventing this type of commercial theft from occurring.

A prosecution office in Qadar, located in the Arabian Peninsula, regularly needs to handle many cases. It requires a large number of paper documents almost every day. Approximately 600 – 1000 documents are generated at the office every day. Due to the frequent loss of documents, the department needed to monitor the entire building. Each document that was ready to leave the building was monitored and ensured that the document was authorized.

The new monitoring system has significantly improved the loss of documents in the prosecution service. The system comes with UHF RFID tags and nearly 1,000 read points. The system allows the prosecution to track documents faster and more accurately. The system provides prosecution agencies with more comprehensive location information. It also provides authorization checks and tag printing modules. The system’s full use allows for much greater security for prosecution agencies.

Patients who go through the admission procedures will get an RFID access card. The access card has an RFID sticker, which has a tracking function. The RFID access card allows the visitor to enter a designated area for activity. An alert will automatically occur if the visitor attempts to enter another restricted room or area using the RFID access card. The system will notify the medical staff first, and someone will then come to check the situation. The use of passive RFID tags greatly enhances patient privacy. It safeguards the security of hospital information.

The use of passive RFID tags can reduce the workload of employees. It prevents employees from coming into contact with contamination sources. There is a medical clinic in Argentina called Sanatorio Finochiettov. It has about 80,000 sheets and clothes; every time they are washed, it is a big job. The popularization and application of passive RFID tags make them handy even in the face of many clothing items. The medical clinic uses passive RFID tags to locate these clothing items’ use, cleaning, and returning.

Passive RFID tags have reduced overstocking. According to the staff associated with the hospital, their hospital has gotten better. Using passive RFID tags allows them to have better information about their inventory. It avoids the purchase of unnecessary supplies. It also greatly reduces the time staff spends counting clothes, allowing them to do other things. It can give you an overview of the entire hospital’s asset inventory, location, and more.

The parking problem has always been a headache for car owners. There is a Chinese saying, “It’s easy to buy a car, but hard to park.” Every day, countless cars are driving on various roads. When night falls, they end up in various parking lots or even on the roadside. Finding a suitable parking space in a crowded city is a problem. Parking lots that use RFID technology can help drivers find the right parking spot.

The city of Moscow, located in Russia, has recently implemented a parking zone control solution. It is a smart parking lot implemented using passive RFID tags with readers. Passive RFID tags are placed on the license plate of each vehicle with RFID readers at the entrance and exit of the parking area. Each vehicle that wants to enter the parking lot needs to be verified by RFID readers. It is confirmation that authorized vehicles will only allow entry. Authorized vehicles refer to residential and corporate tenants’ vehicles. Of course, it also allows paid parking for a small number of vehicles. The promotion and application of passive RFID tags make parking lot management more intelligent.

Tools and equipment have always been an extremely important part of mine plant operations. Every year, companies incur financial losses due to theft or loss of equipment. The use of passive RFID tags can effectively help workers and managers identify and manage equipment.

A diamond mine in Canada has gone one step further by using passive RFID tags to create a secure tracking system. The system requires employees to “check out” the store before using the tool. “Check in” to the store after using the tool. Each employee has a work badge. A staff member scans their badge for checkout or returns when they need or run out of individual items. Items are also scanned to ensure that they are in good condition. An image is also displayed for employee verification after the scan is completed.

Screening for damaged products has always been one of the most important aspects of the supply chain. Selling damaged products can have an extremely bad impact on a company. There is a device on the market that can effectively track shipments and keep track of whether products have been damaged. It can reduce the time as well as the workload of staff screening.

This equipment usually includes a passive RFID tag and an impact indicator. Shock-damaged products are virtually impossible to pass through the supply chain and be rejected. It allows you to know the condition of the packaged product as well. After scanning the package with the RFID reader, the information will upload to the data in real-time. Through the designated software, you can clearly understand the existing condition of the product.

The device can effectively help freight managers to screen potentially damaged products. Inspections can be initiated even while in transit. Passive RFID tags can optimize the supply chain process and reduce the incidence of damaged products for sale.

I believe that after the above, you already have a better understanding of passive RFID tags. It can be used in several industries and is suitable for companies with large-scale physical assets. If you are in the retail or logistics industry, you may consider using passive RFID tags.

-

FAQ 1: What are Passive RFID Tags, and how do they work?

Passive RFID Tags are small electronic devices that use radio waves to transmit data to a reader. They use an antenna to receive energy from the reader and then reflect a signal back to the reader, which contains the tag’s unique identification number.

-

FAQ 2: What are the advantages of using Passive RFID Tags over other types of identification systems?

Passive RFID Tags offer several advantages, including their small size, long read range, and ability to read multiple tags simultaneously. Unlike barcodes, they also do not require line-of-sight and can be read from a distance, making them ideal for inventory and supply chain management.

-

FAQ 3: How do Passive RFID Tags differ from Active RFID Tags?

Passive RFID Tags do not have their own power source and rely on the energy transmitted by the reader to operate. On the other hand, active RFID Tags have their own power source and can transmit data over longer distances.

-

FAQ 4: What are the limitations of Passive RFID Tags, and how can they be addressed?

Passive RFID Tags have limitations such as read range, interference from metal and water, and potential for collisions when multiple tags are nearby. These limitations can be addressed using specialized tags, antennas, and frequency bands.

-

FAQ 5: How are Passive RFID Tags powered, and what is their range?

Passive RFID Tags are powered by the energy transmitted by the reader and have a read range of up to several meters, depending on the frequency and environment.

-

FAQ 6: How can Passive RFID Tags be read, and what equipment is needed?

Passive RFID Tags can be read using an RFID reader, which transmits a radio signal to the tag’s antenna. Then the tag responds with its unique identification number. The reader can be a handheld device or a fixed reader, and the equipment needed to read Passive RFID Tags varies depending on the application.

-

FAQ 7: What is the lifespan of Passive RFID Tags, and how do their material and environmental conditions affect them?

The lifespan of Passive RFID Tags can range from a few years to decades, depending on the material, environmental conditions, and usage. Exposure to extreme temperatures, moisture, and chemicals can affect the lifespan of the tags, as can physical damage.

-

FAQ 8: How are Passive RFID Tags being used in healthcare and medical applications?

Passive RFID Tags are used in healthcare and medical applications for patient and asset tracking, medication management, and inventory control. They can also be used for temperature monitoring, sterilization tracking, and patient safety.

-

FAQ 9: What are the differences between UHF, HF, and LF Passive RFID Tags, and how are they used in different industries and applications?

UHF, HF, and LF refer to the frequency bands used by Passive RFID Tags. UHF tags have a longer read range and are commonly used in supply chain management and logistics. HF tags have a shorter read range and are used in access control and payment systems applications. LF tags have the shortest read range and are used in proximity-based applications such as animal tracking and keyless entry systems.