RFID sensors have become increasingly popular in various industries for tracking and identification. These sensors offer a range of benefits, including improved inventory management and enhanced security. If you want to learn more about RFID sensors, their applications, advantages, and limitations, this blog post is for you. We’ll provide you with an overview of RFID sensors and how they work and tips for choosing the right sensor to meet your needs.

What is RFID: An Overview

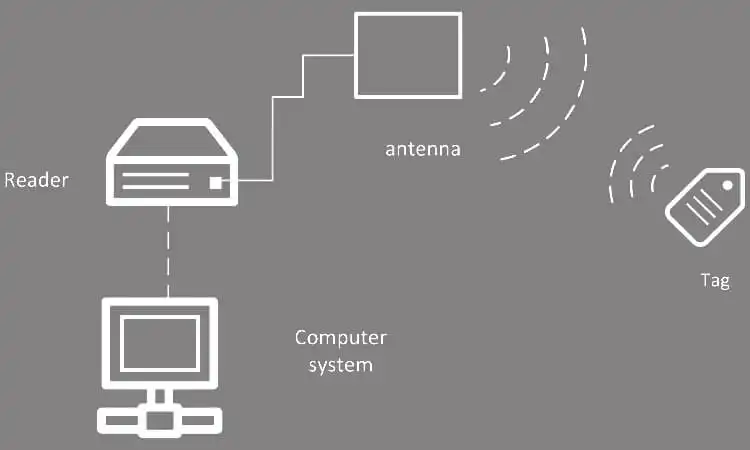

RFID is a type of wireless technology that uses radio waves to identify and track objects. The technology comprises three components: an RFID tag or transponder, an RFID reader, and a computer system. The RFID tag contains a small microchip and an antenna, which together store and transmit data to the RFID reader. The reader, in turn, uses radio waves to communicate with the tag and retrieve the stored data. This enables RFID to provide real-time tracking and identification capabilities, improving efficiency, accuracy, and security.

RFID technology has many potential applications and is often cited as a key technology for the “Internet of Things.” An RFID system typically consists of unique identifiers, similar to barcodes. However, unlike barcodes, RFID tags can be read simultaneously by multiple devices, making them more efficient for tracking purposes. This ability to read multiple tags at once has made RFID technology a popular choice in industries such as logistics, supply chain management, and retail.

RFID tags can also be used in combination with other technologies, such as Bluetooth Low Energy (BLE), to provide additional functionality or security. For example, BLE can be used to provide real-time location tracking of RFID tags, enhancing the accuracy and security of asset-tracking systems.

What Are RFID Sensors?

RFID sensors use radio waves to identify and track items automatically. This wireless technology can store data about assets and provide real-time information. As a result, RFID sensors are widely adopted in industries to improve efficiency and monitor equipment.

Compared to barcodes, RFID tags have major advantages. They can store more data, be read from a distance, and withstand harsh conditions. These “smart barcodes” are ideal for industrial environments.

Businesses use RFID sensors for:

- Inventory management – Track items in stockrooms and warehouses

- Security – Monitor access to restricted areas

- Automation – Guide products through assembly lines

- Asset tracking – Locate high-value equipment

RFID helps companies by:

- Automating processes

- Improving the accuracy of data

- Reducing human errors

- Gaining real-time visibility into operations

How Do RFID Sensors Work?

An RFID sensor consists of two parts: an antenna and a microchip.

The antenna emits radio waves that power the microchip. The microchip stores data that identifies the item it’s attached to.

To read an RFID sensor:

- The antenna emits radio waves that activate the microchip.

- The microchip modulates the radio waves to transmit its identification data.

- An RFID reader decodes the modulated signal to determine the item’s identity.

There are two main types of RFID sensors:

- Active tags have a battery to transmit data over long ranges and track objects in real-time.

- Passive tags use the energy transmitted by the reader’s radio waves. They are smaller, lighter, and cheaper than active tags.

RFID sensors mainly differ in the frequency bands they operate in:

- Option 1: Low frequency (under 125 kHz)

- Short read range of about 2 feet

- Cheaper and higher longevity

- Often used for asset tracking

- Option 2: High frequency (13.56 MHz)

- Read range up to 3 feet

- Better data transfer rate

- Used for contactless payment

- Option 3: Ultrahigh frequency (300 MHz to 3 GHz)

- Long read range up to 100 feet

- High data transfer rates

Ultrahigh frequency (UHF) RFID tags are the most common due to:

- Ability to read multiple tags simultaneously

- Improved read accuracy

- Greater resistance to interference

What Material is Used in an RFID Sensor?

Although we described above that an RFID sensor comprises an antenna and a microchip. However, when fully described, it generally consists of two main parts: an RFID tag and an RFID reader. The materials used in these components can vary depending on the specific application and the requirements of the system.

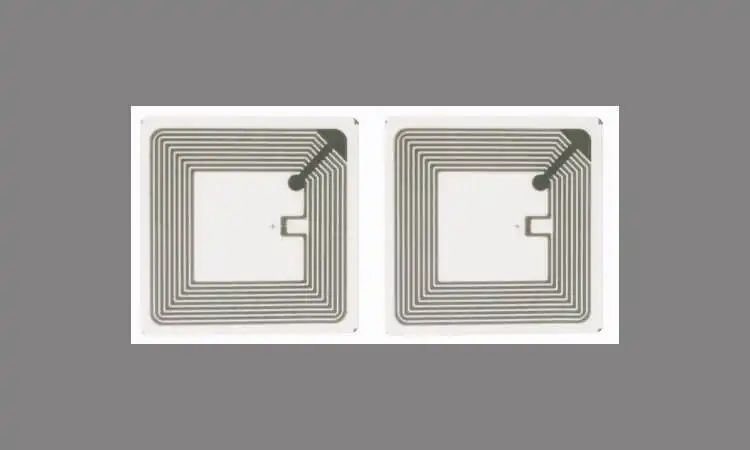

The RFID tag in an RFID sensor is a small electronic device affixed to the object that needs tracking or monitoring. The tag typically contains an integrated circuit (IC) or microchip, an antenna, and a substrate or protective material. The substrate or protective material can be made of various materials, including plastic, paper, or metal, depending on the application.

The microchip or IC in the RFID tag is usually made of silicon and contains an electronic circuit that stores data and communicates with the RFID reader. The antenna in the RFID tag is typically made of conductive materials such as copper or aluminum, and its size and shape can vary depending on the frequency and read range of the RFID system.

The RFID reader in an RFID sensor is the device that communicates with the RFID tag to read the data stored on the tag. The reader typically contains a radio frequency module that sends and receives signals to and from the RFID tag. The reader can be connected to a computer or other device to process and analyze the data collected from the RFID tag.

How RFID Sensors Improve Business Operations

RFID sensors are a powerful technology that can benefit businesses and organizations. These benefits include increased efficiency, improved asset tracking, enhanced safety, and reduced costs.

Efficiency Gains

By deploying RFID sensors, businesses can improve the efficiency of various operations. For example, in a logistics setting, RFID sensors can track the movement of goods and materials. This can help optimize the supply chain and reduce shipping costs.

Inventory Management

RFID sensors also improve asset tracking by providing real-time data on the location and movement of assets. This information can be used to optimize inventory levels, reduce the costs associated with overstocking, and prevent loss or theft of assets.

Safety Improvements

In addition to improving efficiency and asset tracking, RFID sensors can enhance safety in various settings. For example, in a construction site, RFID sensors can be used to track the location of workers and equipment, which can help prevent accidents and improve safety protocols.

Cost Reductions

RFID sensors can help businesses reduce costs by automating tasks such as inventory counts and reducing the need for manual labor. This can result in significant cost savings and improved profitability.

As RFID sensors become cheaper and more portable, the following trends may occur:

- More businesses can deploy RFID affordably

- Companies gain new opportunities to improve via RFID

- Incremental efficiency/cost reduction benefits accumulate

For example, manufacturers might use new portable RFID sensors:

- To track tools/parts on the factory floor in real-time

- Spot deficiencies before they cause downtime or wasted materials

- Adjust processes to maximize throughput

Types of RFID Sensors for Different Applications

RFID sensors are available in various shapes and sizes, each with its own unique features and applications. Understanding the different types of RFID sensors can help businesses choose the most suitable option for their needs.

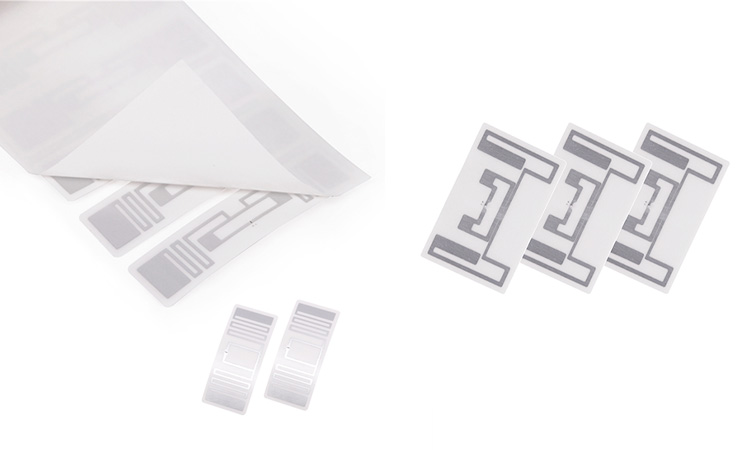

The most common type of RFID sensor is the tag, which is affixed to an object and transmits its ID when queried by an RFID reader. RFID tags are a type of RFID sensor that are commonly used for asset tracking and security purposes. They are available in different sizes and can be customized to suit specific requirements. For example, passive tags do not require batteries and are ideal for applications where changing batteries may be difficult or impractical.

RFID cards are a type of RFID sensor that are commonly used for building access and payment purposes. These cards are inserted into a card reader, similar to a credit card, and communicate with the reader using radio frequency technology. RFID cards can provide secure and efficient access control in buildings, as well as convenient payment options in various industries. They are durable and can be programmed to store various data, making them useful for various applications.

In addition to tags and cards, there are also RFID stickers and labels. RFID stickers are small adhesive sensors attached to nearly any surface. They are often used for promotional purposes or for tracking objects in a confined space. On the other hand, RFID labels are often used for inventory management and supply chain applications.

There are also specialized RFID sensors for specific applications, such as wristbands for events or NFC-enabled sensors for mobile payments. By understanding the different types of RFID sensors, businesses can choose the most suitable option for their specific application and improve their operations.

This can be briefly summarized as follows:

- Option 1: RFID tags

- Attached directly to objects

- Transmit identification when read by an RFID reader

- RFID tag used for:

- Asset tracking

- Supply chain management

- Inventory control

- Security

- Option 2: RFID cards

- Inserted into a card reader

- RFID card common form factors:

- Proximity card

- Smart card

- RFID card used for:

- Building access

- Payment

- Identification

- Option 3: RFID stickers

- Adhesive labels

- Small and flexible

- RFID sticker used for:

- Promotional purposes

- Tracking items in confined spaces

- End product labeling

Different sensor types suit various applications based on the following:

- Object being tracked (pallets, items, people)

- Reading environment (indoors, outdoors, confined spaces)

- Data storage needs (basic ID or extensive data)

What can Affect RFID Sensors?

RFID sensors are a powerful technology for businesses, but several factors can impact their performance. Here are some key factors that can affect RFID sensors:

- Environmental factors: RFID sensors can be affected by environmental conditions such as moisture, temperature, and electromagnetic interference. For instance, high levels of moisture or extreme temperatures can damage RFID tags, while electromagnetic interference can cause signal interference.

- Metal surfaces: RFID signals can be blocked or weakened by metal surfaces, reducing the read range or preventing the sensor from functioning correctly. This is because metal surfaces can reflect or absorb the radio waves used by RFID sensors.

- Interference from other devices: RFID sensors can also be affected by interference from other radio waves, such as Wi-Fi routers or cell phones. This interference can cause signal interference and reduce the read range of the RFID sensor.

- Tag orientation: The RFID tag’s orientation can impact the sensor’s read range and accuracy. If the tag is placed in a non-optimal position, the RFID reader may not read it correctly.

- Tag density: The density of RFID tags in a given area can also impact the performance of RFID sensors. When multiple tags are in close proximity, they can interfere with each other, causing signal interference and reducing the read range of the sensor.

How to Choose the Right RFID Sensors

In addition to the above factors, keep in mind, first, and you need to understand the requirements for your application:

- Condition 1: Environmental Conditions

- Will tags face moisture, dust, chemicals, or temperature extremes? Choose tags designed for those conditions.

- Condition 2: Read Range

- How far must tags be read? Higher frequencies enable longer reads but cost more. Choose a balance of range and cost.

- Condition 3: Tag Size

- Will tags track small items closely or larger assets over a wide area? Match tag size to object size.

- Condition 4: Power Needs

- Do tags need battery life, or can they be wired? Active tags provide longer reads but require battery replacement.

Matching RFID Sensors to Applications:

- Harsh condition requirements dictate tag design/materials

- Needed read ranges to determine optimum frequency bands

- Object sizes being tracked dictate minimum tag sizes

- Power source (battery vs. wired) affects lifetime cost vs performance

Once you understand these key application variables:

- Compare various tag, reader, and antenna options

- Evaluate sensor system read ranges at different frequencies

- Test suitable tag sizes and placements on real objects

- Determine battery-powered vs. wired system total costs of ownership

Then select the sensor configuration that best fulfills your application’s unique environmental, performance, and economic requirements.

The advent of RFID sensors has gradually changed the way businesses track and monitor their assets. With their ability to provide real-time data and improve efficiency, RFID sensors have become a crucial tool in a variety of industries. By utilizing the right RFID sensor and understanding the factors that can affect its performance, businesses can optimize their operations, reduce costs, and improve their bottom line.