Sensors and actuators are often found in the same area of industrial environment equipment. They are the basic elements of embedded systems. In the same environment, they each have their role and depend on each other. Sensors are mainly used to track the condition of a device or environment. Conversely, Actuators control the events or environment within the device. Next, let’s discuss the definitions and differences between sensors and actuators.

What is a Sensor?

The sensor is a device that monitors any changes that occur in the physical environment. These environmental changes include temperature, humidity, vibration, and pressure changes. The sensor converts these physical parameters into electrical signals. They then send this data or alarms to a central system for the user to view. They also automatically adjust for specific devices. For example, if a motor exceeds a specific threshold temperature, it will automatically shut down.

The following are eight of the more common types of sensors:

- Vision sensors: These usually use images to determine a certain state of a particular object. Such as the presence, orientation, and accuracy of objects.

- Temperature sensors: This type of sensor can be used in the food service industry. They can be effective in preventing food spoilage.

- Vibration sensors: These sensors help to measure the vibration levels of sensitive assets. People mostly use it for rotating machinery.

- Safety sensors: Sensors that help companies keep employees safe in their facilities. They also help companies keep track of expensive tools and equipment.

- Pressure sensors: Pressure changes in physical assets and changes their performance. Pressure sensors alert users when they detect pressure changes that could state a potential failure.

- Moisture sensors: Sensors primarily used to control trace amounts of moisture. They help avoid the effects of moisture factors on some extremely sensitive electronics.

- Gas sensors: Sensors that sense the concentration of gases. People use them in a wide variety of industries. Gas sensors alert the user when a gas concentration is too high or too low.

- Inertial sensors: A sensor that detects and measures an object’s acceleration, tilt, and vibration. They are important for solving navigation, orientation, and motion carrier control.

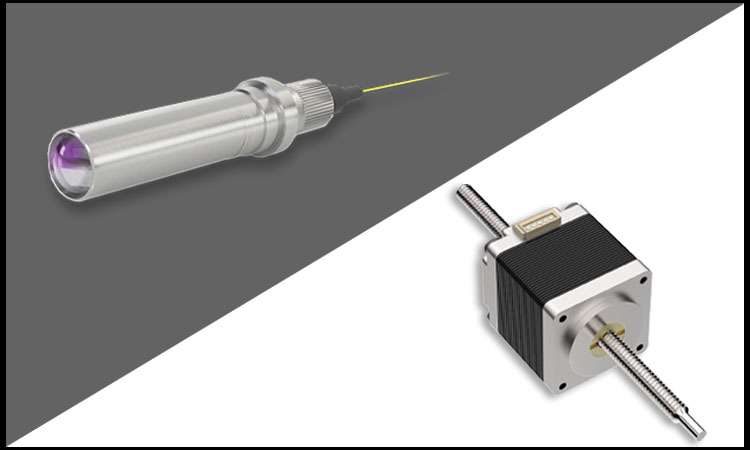

What is an Actuator?

The actuator is a device that can change a physical quantity. It can convert electrical signals or electricity into mechanical energy. Actuators can be used to create motion or make environmental changes. Some common examples are the use of fans to help reduce temperatures. Servo motors can be used to drive specific control objects. Most of these actuators are guided by software. They translate control signals into spontaneous actions. There are many types of actuators. They can be manual, pneumatic, hydraulic, electric, and spring-loaded.

The following are the five different types of actuators:

- Manual actuators: An actuator requires manual user manual control of gears, bars, or wheels. They do not need a power source and are inexpensive. They also have a distinct disadvantage – limited applicability.

- Pneumatic actuators: Actuators that primarily use air pressure to power the valve. They use pressure to push the piston and thus affect the valve stem.

- Hydraulic actuators: These actuators use fluid to generate pressure. They differ from pneumatic actuators because they use fluid pressure to operate the valve.

- Electric Actuators: Actuators that operate the valve in a manner that is accomplished by an electric motor. They are quiet and exceptionally efficient to use. However, they need batteries or electricity and are unavailable in certain locations.

- Spring Actuators: This actuator must be kept in a rebound state until a trigger occurs. Whenever the spring actuator reaches a specific threshold, the spring releases and operates the valve. This actuator is typically used for one-time emergency applications.

Sensor and Actuator Difference

Sensors and actuators are important components in any machinery. They have quite a few differences in their function or handling. Here we list 8 of these differences between sensors and actuators.

Definition

A sensor is a device designed to sense and measure events or changes in the environment. It also sends the collected information to other electronic devices. On the other hand, an actuator is a machine component. It converts electrical signals into mechanical work.

Dependencies

Sensors and actuators are dependent on each other. They can depend on each other to perform a given task. In the presence of both, the actuator relies on sensors to do its job. System malfunctions when one or both of them are not functioning properly.

Connections

A sensor is usually connected to the input port of the system. The actuator is the opposite and is connected to the output port of the system.

Usage

One of the main differences between sensors and actuators is their usage. Sensors are primarily used to track changes in the environment. On the other hand, actuators help the researcher control environmental or physical changes.

Inputs

Sensors primarily take input from the environment. The way the actuator gets its input through the system or signal conditioning unit.

Output

The sensor outputs an electrical signal to the outside world. The electrical signal reads the specific environmental conditions and performs the assigned tasks. The actuator is different in that it outputs motion. It determines the ability to generate a specific action by measuring heat or movement. The difference in output is very obvious between sensors and actuators.

Power

A sensor may or may not need more power to operate. On the other hand, Actuators must have extra power to operate properly.

Sensor and Actuator Applications

Sensors such as biosensors, image, and motion sensors will be used to measure asset temperature and vibration. More industrial applications for actuators are operating dampers, valves, and couplings.

Here’s a table outlining the main differences between sensors and actuators:

| Sensors | Actuators | |

|---|---|---|

| Definition | Devices that detect and measure physical quantities. | Devices that convert electrical signals into physical motion or force. |

| Function | Detect and measure physical quantities, such as temperature, pressure, and light. | Convert electrical signals into physical motion or force, such as driving mechanical systems or opening and closing valves. |

| Input | Physical quantities | Electrical signals |

| Output | Electrical signals | Physical motion or force |

| Examples | Temperature sensors, pressure sensors, motion sensors, light sensors | Motors, solenoids, pneumatic and hydraulic actuators |

| Applications | Monitoring environmental conditions, detecting objects, measuring physical activity | Driving mechanical systems, controlling fluid flow, opening and closing valves |

| Use in IoT | Collecting and transmitting data from remote locations | Controlling systems and devices in remote locations |

Examples of Sensors and Actuators

Mechanics

A typical example of a mechanical sensor is the Barometer sensor, which measures atmospheric pressure. The barometer tube of this sensor is filled with mercury. The amount of mercury in the tube increases whenever the atmospheric pressure increases. They are proportional to each other.

A common example of a mechanical actuator is a device called a screw jack. If one tightens or rotates the screws of this device, its legs move. Here, the mechanical actuator converts mechanical rotation directly into linear motion.

Electrical

Electrical sensors are primarily used to sense and measure the flow of electricity through a conductor. There are several different energy conversions involved in this process. Such as converting an electrical signal to a magnetic signal and converting this signal to a mechanical signal.

Electric motors belong to the category of electric actuators. This type is a DC motor. DC motors usually operate through an electric current running around a coil. It causes a magnetic field to appear around the coil. Electric actuators create this magnetic field when converting electrical energy to magnetic energy. The motor then outputs the magnetic energy as a mechanical output in the form of motion.

Automotive

The sensors operating in a vehicle are designed to determine the state of the fuel. One can use the sensors to know if the fuel is firing or is in a smooth stateIgnited fuel can cause major damage to a car. Such as broken engine rings and abnormal bearings. The presence of sensors allows us to avoid these problems. Sensors help the user know exactly how well the fuel is burning or cooling in the vehicle. Excessively cold fuel can affect the operating condition of the vehicle. The fuel in that state is denser, limiting the car’s smooth running.

Actuators control the useless speed of the car in the car engine. The actuator supports the regulation of air chatter and enhances its force. The actuators manufactured with this technology help to provide adequate safety to the users riding in the car. Actuators can also be applied to control redistribution or exhaust gas. And it does so through this capability to gain performance improvements.

Hydraulic

The hydraulic sensor is one of the sensor applications that are quite popular in water distribution. The sensors are mainly used to make measurements of the pressure and flow of water. These sensors can also be used as gauges. The sensors are also used in water distribution systems to measure instantaneous pressure and pipe bursts. The sensors also support the measurement of the flow rate of water. People mostly use electromagnetic and vortex measurements as flow meters in practical applications.

A hydraulic actuator with a piston that slides easily contains a cylindrical hollow tube inside the body. Applying pressure to only one side of the piston is called the one-way movement of the piston. The movement is also called single-acting. The spring present in it is used as a return stroke during the unidirectional movement of the piston. Another common type of pressure action is called double acting. Double acting applies pressure on both sides of the piston. The two sides of the piston are subjected to different pressure conflicts that allow the piston to move.

Robotics

Sensors are widely used in robotics and occupy an extremely important position. The use of sensors provides robots with human-like perceptual functions and responses. The use of sensors in robotics also helps to improve the performance of robots. Using sensors in these robots allows them to act externally like human beings.

On the other hand, actuators are used for mechanical movements in this condition. In simple terms, they are the muscles of the robot.

Sensor and actuator difference is clear. Sensors focus on monitoring, while actuators focus on control. One collects information, and the other executes the commanded action. Both sensors and actuators are the components that make machines work efficiently. They allow equipment to maintain and improve its operating state.

About Sensors and Actuators FAQs

-

What are sensors and actuators, and how do they differ?

Sensors detect and measure physical quantities, such as temperature, pressure, and light. Actuators such as motors or solenoids convert electrical signals into physical motion or force. Sensors and actuators work together in many electronic devices to enable automation, control, and feedback functions.

-

What are the different types of sensors, and how are they used?

There are many different types of sensors, including temperature, pressure, proximity, and motion. They are used in various applications, such as monitoring environmental conditions, detecting objects, and measuring physical activity.

-

How do sensors and actuators work together in electronic devices?

Sensors detect physical quantities and convert them into electrical signals, which are then processed by a control system. The control system then sends signals to actuators, converting electrical signals into physical motion or force. This allows electronic devices to sense and respond to changes in the environment or user input.

-

What are some examples of sensors and actuators used in everyday life?

Examples of sensors and actuators used in everyday life include temperature sensors in thermostats, motion sensors in security systems, and motors in appliances such as washing machines and air conditioners.

-

How do sensors and actuators improve industrial processes and manufacturing?

Sensors and actuators can be used in industrial processes and manufacturing to monitor and control temperature, pressure, and flow rate. This can improve efficiency, reduce waste, and enhance product quality.

-

What are the benefits of using sensors and actuators in robotics and automation?

Sensors and actuators are essential for robotics and automation, allowing machines to sense and respond to their environment. This can improve manufacturing and other industries’ precision, speed, and safety.

-

What are the advantages of using wireless sensors and actuators in IoT applications?

Wireless sensors and actuators can be used in IoT (Internet of Things) applications to collect and transmit data from remote locations. This can improve efficiency, reduce costs, and enable new applications like smart homes and cities.

-

How are sensors and actuators used in smart homes and buildings?

Sensors and actuators can be used in smart homes and buildings to automate lighting, heating, and security functions. For example, motion sensors can turn lights on and off automatically, and smart thermostats can adjust temperature settings based on occupancy and weather conditions.