The Internet of Things (IoT) can transform the food supply chain. Connecting devices, machines, and people across the food supply chain can deliver many benefits. These include improved food safety and transparency, increased visibility into product movement and inventory levels, better asset utilization, improved compliance with regulations and standards, reduced operating costs, and increased efficiency through better information sharing between partners in the supply chain.

Why do We Need Food Supply Chain Management?

We need to raise awareness about food waste

Ineffective food supply chain management can seriously affect public health and food access. When the flow of food is not planned, implemented, and controlled correctly, food shortages, price spikes, and waste can occur. Moreover, poor communication and collaboration among stakeholders can exacerbate the situation. The growth of the agriculture and food industries may also be affected negatively. Overall, proper food supply chain management is crucial for ensuring food availability and accessibility for everyone.

The City of Westminster’s official website mentions the importance of food supply chain management:

According to the United Nations, food waste can also be defined as “any removal of food from the food supply chain which is or was at some point fit for human consumption.” The UN says that this is “mainly caused by economic behaviour, poor stock management or neglect.”

How does Food Supply Chain Management Differ from Traditional Supply Chain Management?

Food supply chain management differs from traditional supply chain management in several ways.

Firstly, the food supply chain is highly regulated. Strict laws and regulations often govern food products’ production, distribution, and sale. These regulations aim to ensure the safety and quality of food produced and consumed. And they often require additional monitoring, tracking, and reporting requirements.

Secondly, the food supply chain is highly perishable, and the products have a limited shelf life. This means that food supply chain management must carefully manage inventory levels. They must minimize waste, spoilage, and damage.

Thirdly, the food supply chain often involves many parties, including farmers, processors, distributors, wholesalers, retailers, and food service providers. This complexity requires effective coordination and collaboration between all parties to ensure. They must ensure the right products are available at the right time and place.

Fourthly, consumer demand for food products can be highly variable. The food supply chain must be flexible enough to adapt to changes in demand. This may require predictive analytics to forecast demand and adjust production levels accordingly.

Finally, the food supply chain is often more susceptible to supply chain disruptions. Such as weather events, disease outbreaks, and transportation issues. Therefore, food supply chain management must have robust contingency plans. This plan ensures that products can still be delivered to consumers during a disruption.

This table compares food supply chain management and traditional supply chain management:

| Category | Food Supply Chain Management | Traditional Supply Chain Management |

|---|---|---|

| Objectives | Ensure food safety and quality | Increase efficiency and profitability |

| Stakeholders involved | Farmers, suppliers, processors, distributors, retailers, and consumers | Manufacturers, suppliers, distributors, retailers, and consumers |

| Unique challenges | Seasonality, perishability, and regulatory compliance | Inventory management, transportation, and logistics |

| Traceability | Essential to track and trace products from farm to fork to ensure safety and quality | Not always necessary, but becoming more important for product recalls and quality control |

| Technology | Increasingly reliant on digital tools for tracking, inventory management, and quality control | May use some digital tools, but not always to the same extent as in food supply chain management |

| Sustainability | Focuses on reducing waste and emissions, promoting local and organic food production, and ethical sourcing | May consider sustainability, but not always a top priority |

| Consumer behavior | Consumers are increasingly interested in knowing the origin of their food, its production process, and sustainability practices | Consumers may be more concerned with price and convenience |

IoT in Food Supply Chain Management Benefits

Food Loss and Waste Reduction

Food loss and waste reduction are big problems. According to the United Nations, it’s estimated that 30% of all food produced for human consumption is lost or wasted globally. In developed countries, food waste occurs at all supply chain stages, from production through processing and distribution to consumption. However, in developing countries, most losses occur during harvesting, storage, and transportation before reaching markets or consumers’ homes.

Food loss can be defined as any decrease in the quantity or quality of food due to spoilage or damage caused by pests. In contrast, food waste refers to edible food discarded by retailers or consumers which could have been consumed if properly stored and prepared.

The United Nations Food and Agriculture Organization (FAO) estimates that 1.3 billion tons of food are lost or wasted each year, including 31% of all fruit and vegetables, 35% of fish and seafood, and 30% of cereals and dairy products. In addition to a significant economic loss — US$750 billion annually — this food waste also impacts the environment.

Real-time Food Tracking

Real-time food tracking is vital to any supply chain management system, and IoT technology offers several benefits. First and foremost, it allows you to keep track of the location and condition of your products at all times.

Secondly, it helps you identify any issues that may arise during the transportation process so that they can be addressed before they become serious problems. Finally, real-time tracking provides valuable insights into how well your business is operating as a whole–you’ll know exactly where there are opportunities for improvement when it comes time to planning next year’s budget!

IoT technology can also help you track the shelf life of perishable items. Using sensors to monitor temperature, humidity, and light levels in your warehouse, you’ll be able to keep tabs on how well your products are stored. This will allow you to adjust the climate controls in your distribution centers as needed and prevent spoilage from occurring.

You can use IoT technology to prevent theft. For example, IoT sensors can be placed on each package to monitor their locations if you’re shipping valuable products. This will allow you to determine if any items have gone missing and take appropriate action.

Increased Food Supply Chain Management Safety and Transparency

You can use IoT to improve safety and transparency in the food supply chain. Food safety is everyone’s responsibility, and real-time tracking allows for better oversight of products at every step of the way. This helps reduce foodborne illness outbreaks, prevent contamination and fraud, and reduce waste throughout the process.

By tracking food from farm to fork, we can keep tabs on the temperature at which it’s stored and how long it has been there. This helps prevent outbreaks of foodborne illnesses like E. coli and salmonella, which can be traced back to improper handling or storage of meat products.

IoT can track the temperature and humidity of storage areas, helping prevent spoilage. This means a lot in places like California, where farmers reduce waste by up to 50% thanks to IoT technology.

The same goes for the transportation process. Tracking the temperature and humidity of trucks and containers ensures that perishable items are properly preserved during transport. This has a direct impact on food safety while also preventing waste.

Improve Compliance

The IoT can help you ensure compliance with food safety regulations, food chain regulations, environmental regulations, health regulations, and consumer and animal welfare regulations.

You can use the IoT to monitor your products throughout their entire lifecycle by tracking them at every production stage. This will help you meet all federal and state safety, quality control, and government regulatory requirements.

You can use IoT to monitor product quality and safety. By tracking temperatures, humidity levels, and other product characteristics throughout the production process, you can ensure that all products meet your standards for quality. You can also use it to track your products as they move through the supply chain, ensuring they don’t become contaminated during transportation or storage.

Increase Efficiency and Productivity

IoT technologies can increase efficiency and productivity in the food supply chain by providing real-time information about inventory, production, and sales. This information allows manufacturers to allocate resources across their business operations better.

For example, when manufacturers can measure their inventory levels accurately and quickly, they can identify where there is too much or too little product at any given time. Thanks to this knowledge base, they can adjust production plans accordingly always to have sufficient stock. At the same time, they can reduce the costs associated with excessive waste caused by over- or under-production in the system.

IoT technology also enables companies like yours (or anyone else) to do business in the space, like Loblaw Cos or others. Still, more IoT companies have announced plans to implement new technology solutions designed specifically for grocery stores or large chains like Walmart. They expect its entire supply chain infrastructure, including distribution centers across North America, will eventually include some form of smart device connectivity within one year. These organizations could benefit greatly from using artificial intelligence applications such as cognitive computing tools. Because these technologies allow humans to work together side-by-side without having access to each others’ brains via computer screens all day long.

Reduce Operating Costs

In the food supply chain, many benefits can be achieved by using IoT technology. The first is reduced operating costs. This includes reducing inventory management, transportation, and labor costs. There are also savings in waste disposal and spoilage prevention through better tracking of production processes; producers can predict when supplies will run out based on their experience or knowledge about peak periods for demand (such as holidays).

The second benefit is improved efficiency in distribution and delivery times which leads directly into point three: improving customer service through faster response times from automated notifications informing them when their order has shipped out. Hence, they know when they can expect delivery/pickup, etc.

Improve Asset Utilization

The IoT can improve asset utilization. Asset utilization is the most important factor for a company’s long-term profitability. It’s even more important than revenue or profit because it affects how much money you have to pay taxes and other expenses in your business over time.

IoT technology allows companies to track their assets better than ever before, which means they can:

- Increase efficiency by using data from sensors on equipment or machines that measure real-time performance metrics such as operating temperature, pressure, and vibration levels;

- Increase value by collecting data about the health status of equipment like pumps & compressors (for example);

- Improve effectiveness by providing alerts when problems occur so they can be fixed quickly instead of waiting until something breaks down completely before deciding what needs fixing first;

Improved Food Supply Chain Inventory Management

Inventory management is a critical function in the food supply chain, and it is important to track inventory to ensure it is used efficiently. It’s also important to track inventory to ensure the proper use of your products and services. To demonstrate this fact, we will provide some examples of real-time technology projects in food supply chain management in which our clients have implemented IoT solutions:

- A convenience store chain wanted to improve its customer service by using smart devices like sensors on shelves or point-of-sale machines. They can use these devices to tell whether customers have paid for their items (or at least how far those customers have traveled) before they leave the store. This information would allow the store manager to issue refunds or bill backs without having human interaction with them—and without making people wait too long.

- A food manufacturer wanted its employees who work at delivery stations near restaurants where it provides deliveries from trucks directly into refrigerators instead of having drivers bring boxes into refrigerators themselves (which means fewer trips per day). By using sensors on each delivery vehicle’s windshields and a smartphone app designed specifically for those vehicles’ routes, drivers could see exactly when orders were due based on GPS coordinates sent. GPS satellites from satellites orbiting high above Earth’s surface up through geostationary orbit around 23 000 kilometers away from Earth’s surface – meaning they are always visible even though they’re not moving very fast!

Preventive Maintenance

Preventive maintenance is a way of ensuring that the equipment is working as it should. It can help avoid equipment problems, such as breakdowns or losses, which may result in higher costs and reduced productivity.

The benefits of preventive maintenance are many:

- Reduced operating costs – This includes staff salaries to maintenance contractors’ fees; when equipment is properly maintained, you don’t have to pay for it anymore.

- Improved equipment utilization – If you know what issues exist within your industry’s supply chain management system but aren’t sure how best to fix them. Then one option would be investing time into researching these problems before bringing in outside help from experts specializing in IoT technologies. Examples include smart sensors embedded into industrial processes like food production lines so that they can collect data about those processes over time.

Improved Food Supply Chain Logistics

Logistics is managing the movement of goods from one location to another. It is a key part of any food supply chain because it helps to reduce costs and improve efficiency.

Food supply chain management involves coordinating and integrating all that occurs within the food supply chain (processing, distribution, and sales). The first step in improving food supply chain management is defining your problems so you can begin solving them effectively. You should also investigate what’s happening at every stage along your route before taking action on anything else!

Digitalization of Paper-based Records

Paper-based records are a waste of time and money. Food supply chain management has always been challenging, but it’s getting harder than ever. For example, in the past five years alone, we’ve seen an increase of 1.5 billion people worldwide who don’t have access to enough food—and that number is expected to rise by another billion by 2030.

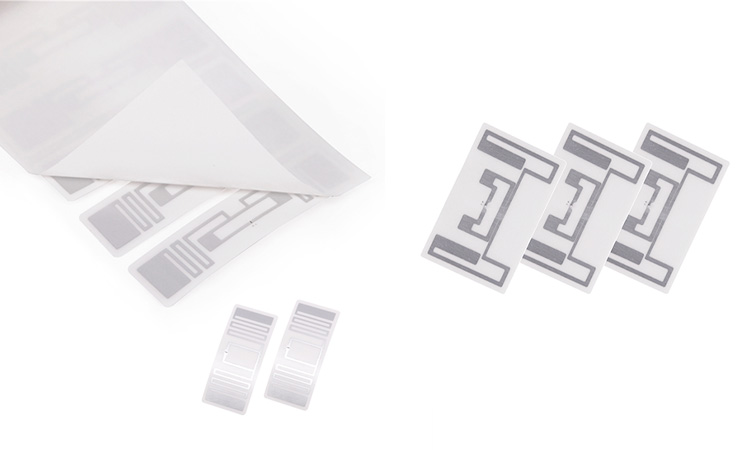

In this scenario where demand outstrips supply, how can we help ensure that every person gets nutritious food? The answer: through IoT technology! By digitizing paper records such as receipts with IoT sensors at every point of our farm-to-table (and even earlier) production cycle and Bluetooth or NFC technology, we can ensure Everything when packed through our supply chain. It ensures we track them accurately, without errors or delays, and without wasting resources on redundant paperwork like shipping manifests or invoices.

Enhanced Brand Value

Brand value is the sum of all consumers’ positive and negative associations, beliefs, and perceptions about a brand. It’s determined by how customers perceive it—and that perception matters because it influences their willingness to buy from you. The higher your company’s brand equity (BrandEQ) or its perceived value among customers, the more likely they will purchase from you over other brands in your industry.

Achieving this high level of trust requires understanding who your audience segment is and what they want out of life—because each person has different needs at different life stages. Understanding those needs through research into demographics such as age groups or income brackets, learning more about lifestyle preferences like food preferences, and identifying common interests such as sports teams, etc. One way businesses can do this is by using segmentation techniques like demographic analysis, which allows them to identify specific societal groups based on similarities between people within these segments rather than just looking at broad categories like gender/race.

IoT can be a great way to improve the efficiency of food supply chain management. The technology has been proven effective in reducing waste and improving product quality. It also helps companies track their inventory more closely, so they can increase sales while cutting costs at the same time.

Video Source: City of Westminster’s official website

About Food Supply Chain Management Q&A

-

How can Food Supply Chain Management be Optimized to Reduce Food Waste and Improve Sustainability?

Food waste is a significant issue in food supply chain management, with an estimated one-third of all food produced globally going to waste. Reducing food waste requires careful inventory management, efficient transportation and storage, and innovative solutions for repurposing or donating surplus food.

-

How can Technology Improve Food Supply Chain Management Through Blockchain and AI?

Technology can play a critical role in optimizing food supply chain management. For example, blockchain can track product movement and ensure transparency and accountability, while AI can help companies predict demand and optimize production and distribution processes.

-

What are the main risks associated with food supply chain management, such as contamination and supply chain disruptions?

Risks associated with food supply chain management include contamination, supply chain disruptions, and food fraud. Companies can mitigate these risks by implementing quality control processes and traceability systems.

-

What are the implications of globalization on food supply chain management, and how can companies manage risks associated with international trade?

Globalization has both positive and negative implications for food supply chain management. On the one hand, it allows access to a wider range of food products and markets. On the other hand, it can increase the risk of supply chain disruptions and introduce new food safety risks. Companies must manage these risks by implementing robust quality control and traceability systems.