Radio-frequency identification (RFID) technology has revolutionized supply chain management recently. By using RFID tags and readers, companies can monitor the movement and location of products and materials at every stage of the supply chain. It brings many benefits to companies. These include increased efficiency, accuracy, and transparency. In this article, we’ll explore the role of RFID in supply chain management. And how you can use it to streamline operations and improve transparency.

What is RFID and How Does it Work?

RFID has been around for decades but has recently gained popularity in improving supply chain management. By using RFID technology, companies can track the movement of goods from the point of manufacture to the point of sale. RFID provides real-time visibility into their supply chain. It can help companies identify bottlenecks. It can also reduce inventory levels and improve customer service.

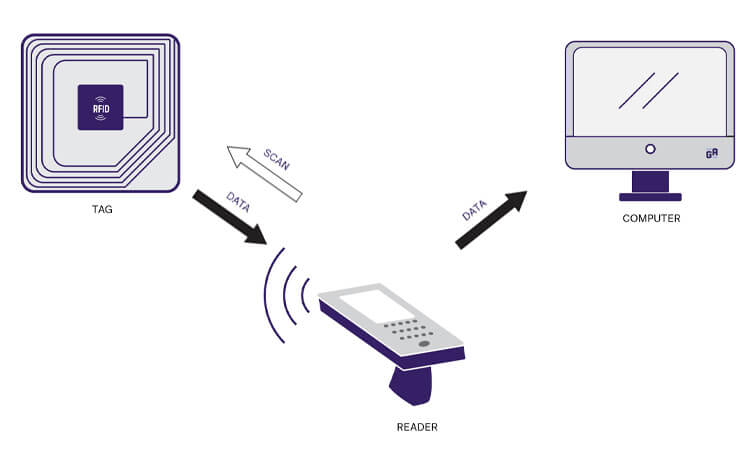

RFID technology consists of three main components: a tag, a reader, and a database. The RFID tag is a small chip with an antenna. It mainly transmits information to the reader. It is adaptable, and you can attach them to almost any object. It allows you to attach it to pallets, boxes, or individual products.

RFID readers are devices that can detect and communicate with RFID tags. They can be stationary or mobile and transmit data to a computer for processing and analysis. A database is a software system that stores and manages the data collected by the RFID system.

Benefits of RFID in Supply Chain Management

One of the main benefits of RFID in supply chain management is tracking and locating goods in real time. Attaching RFID tags to products, companies can accurately track the movement of goods throughout the supply chain. It allows tracking of goods from the point of manufacture to the point of sale. It allows for more efficient inventory management and the ability to respond quickly to changes in demand or supply. It also has these amazing benefits:

Improved Accuracy

In addition to real-time tracking, RFID improves supply chain management accuracy. By using RFID tags and readers, companies can track the exact location of their products and materials in the supply chain. It helps eliminate errors and inaccuracies often present in traditional manual tracking and barcoding systems. Additionally, RFID tags can be attached to products and materials to provide detailed information about them, such as size, weight, and other product specifications. It allows companies to understand their inventory better and provide customers with accurate information about the products they purchase.

Enhanced Visibility

RFID systems provide businesses with enhanced visibility into their supply chain operations. Businesses can comprehensively understand their operations by collecting data from RFID tags at various points in the supply chain. It can help to identify bottlenecks, optimize processes, and improve overall efficiency.

RFID Security in Supply Chain Management

Another major benefit of RFID is its ability to improve security within the supply chain. By tagging products with RFID chips, every item can be identified and tracked, reducing the risk of theft and other loss and providing companies with a record of who purchased the items. This increased security also helps to ensure that the quality of the products being shipped remains consistent. RFID will also allow companies to track when and where they produce the item, ensuring that only top-quality products are distributed in the market.

Reduce Paperwork and Manual Processes

RFID can reduce paperwork and manual processes within the supply chain. Instead of manually entering data into a database, RFID provides instant access to information such as product location, expiration dates, and other important details, helping to streamline operations further and reduce waste. This can result in greater efficiency and cost savings, ultimately boosting the company’s bottom line.

Cost Savings

Implementing an RFID system can also lead to cost savings for businesses. By reducing errors and improving efficiency, RFID can reduce the need for manual labor and increase overall productivity. In addition, RFID systems can help to reduce the risk of lost or stolen goods, leading to cost savings further.

RFID in Supply Chain Management Automates Many Processes

Furthermore, RFID technology can automate many processes related to supply chain management. Automated processes, such as reordering and restocking, can save companies time and money and reduce manual labor. Additionally, RFID technology can be integrated with existing systems, such as enterprise planning and warehouse management systems, allowing companies to gain better control over their supply chains.

RFID in supply chain management offers an array of benefits that can help to optimize the entire process, resulting in greater accuracy, efficiency, and cost savings. By implementing this powerful technology, companies can improve their supply chain’s visibility, tracking, and security while reducing the time and money spent on manual processes. Ultimately, this can translate into a more profitable and efficient business.

Applications of RFID in Supply Chain Management

There are many different ways in which RFID can be used in supply chain management. Some common applications include:

- Inventory Management: By attaching RFID tags to products and materials, companies can easily track and manage inventory levels. RFID can help reduce the need for manual counting, improve accuracy, and alert businesses to any discrepancies.

- Asset Tracking: RFID can track and monitor the movement and location of assets such as equipment, tools, and vehicles. This can help to improve efficiency and reduce the risk of loss or theft.

- Supply Chain Visibility: RFID can provide real-time visibility into the movement and location of products and materials throughout the supply chain. This can help to improve transparency and reduce the risk of delays or bottlenecks.

Case Studies: Successful Implementation of RFID in Supply Chain Management

There are many successful examples of RFID being used in supply chain management. Some notable case studies include:

- Walmart: Walmart was one of the first companies to adopt RFID technology in its supply chain. Using RFID tags and readers, Walmart improved its inventory accuracy and reduced out-of-stock situations by 25%.

- Delta Air Lines: Delta Air Lines implemented RFID technology to track and monitor the movement of luggage throughout its supply chain. Using RFID, Delta reduced the number of lost bags by 50% and improved the efficiency of its baggage handling process.

- Procter & Gamble: In 2005, Procter & Gamble implemented RFID technology in its supply chain to improve the accuracy and efficiency of its inventory management. The company saw a 25% reduction in out-of-stock items and a 50% reduction in inventory carrying costs.

- Nike: In 2007, Nike implemented RFID technology in its supply chain to track the movement of goods from the factory to the store. The company saw a 20% reduction in lead time and a 10% reduction in inventory carrying costs.

- DHL: DHL, a global logistics company, has implemented RFID technology in its supply chain to track and trace packages and improve the efficiency of its delivery process. This has allowed the company to reduce the risk of lost or misplaced packages. It improves the overall accuracy of its operations.

Implementation of RFID in Supply Chain Management

Implementing RFID in a supply chain can be complex, but it is worth it for its benefits. The first step is to identify the areas where RFID can be used, such as tracking products, pallets, or containers. Next, RFID tags and scanners need to be purchased and installed. Choosing the right RFID technology for the company’s specific needs is important. Finally, you must integrate the RFID system with the company’s existing computer systems and processes.

Challenges and Limitations of RFID in Supply Chain Management

While RFID technology has many benefits, there are also challenges to consider when implementing it in supply chain management.

- Cost: One of the main challenges of implementing RFID is the cost. RFID tags and readers can be expensive, especially for companies with large supply chains or many products. However, the long-term benefits of RFID can outweigh the initial costs, as it can help to reduce errors, improve efficiency, and increase profitability.

- Integration: Another challenge is integrating RFID technology into existing systems and processes. This can require significant time, resources, and employee training. It may also involve updating or replacing existing systems, which can be a significant undertaking.

- Privacy concerns: Some people have raised concerns about the privacy implications of RFID technology. While RFID tags do not contain personal information, there are concerns about the ability to track the movement and location of products and materials. Companies must be transparent about their use of RFID and comply with privacy laws and regulations.

- Compatibility: you need to ensure compatibility between different RFID systems and that you can integrate the technology into existing systems and processes.

- Limited Range: RFID tags have a limited range and may not be able to transmit data over long distances or through certain materials. This can be a limitation in certain situations, such as when tracking goods in a large warehouse or when the goods are packaged in metal containers.

RFID vs. Barcode: Which is Better for Supply Chain Management?

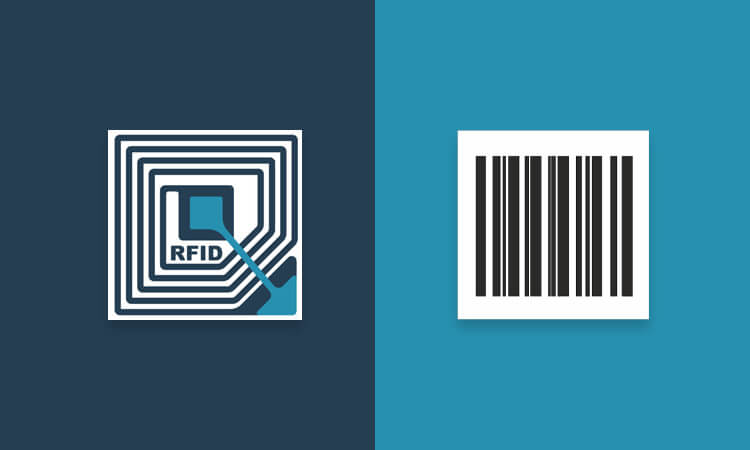

While both RFID and barcodes have their benefits and limitations, RFID technology has several advantages over barcodes in the supply chain.

RFID tags can store more information and be read at a distance, making them more efficient and accurate for tracking and tracing goods.

RFID tags do not require line-of-sight to be read, making them more versatile and easier to use in certain situations, such as when tracking goods in a warehouse or on a pallet.

RFID in the Future of Supply Chain Management

RFID technology is constantly evolving and improving, and it is likely to play an even bigger role in supply chain management in the future. Some of the trends and developments to watch for include:

- Wider adoption: As RFID becomes more affordable and easier to implement, it will likely be adopted by more companies across various industries.

- Enhanced functionality: RFID technology is becoming more sophisticated, and new capabilities are constantly being developed. For example, RFID tags can now be embedded with sensors that can provide additional data, such as temperature or humidity.

- Increased use of the Internet of Things (IoT): RFID technology is closely related to the IoT, which is the interconnected network of devices that can collect and exchange data. As the IoT continues to grow and develop, RFID will likely play an increasingly important role in supply chain management.

One potential area where RFID could significantly impact is traceability and transparency. You can use RFID tags to track and trace goods from the source to the final destination, providing more detailed information about the origin and journey of products. This could help improve supply chain visibility and accountability and be particularly useful in industries such as food and beverage, where traceability is critical.

RFID could also be used to improve the efficiency and accuracy of inventory management and optimize transportation and logistics. RFID can optimize routes and reduce the risk of lost or misplaced goods by providing real-time tracking and tracing data.

RFID in supply chain management can bring significant benefits, including increased efficiency, accuracy, and visibility. While there are challenges and limitations to implementing RFID, the benefits are significant, and the technology is likely to play an increasingly important role in the future of supply chain management.