RFID technology is everywhere, and it exists in many industries. We probably know it more for its presence in healthcare, logistics management, etc. However, RFID technology in food industry can add a different style. This technology offers a wide range of benefits to food companies, retailers, and consumers. Food RFID facilitates supply chain optimization. It can also help restaurant and bar operators improve their operational strategies.

What is RFID in Food?

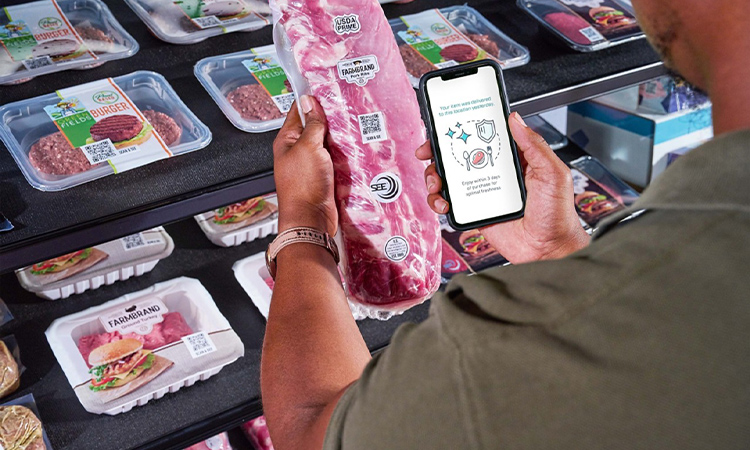

RFID in food refers to using radio-frequency identification (RFID) technology in the food industry. RFID technology uses radio waves to transfer data between a tag or label attached to a food product and a reader device. This allows for real-time tracking and monitoring of food products throughout the supply chain, from farm to fork.

So How does Food RFID Work?

Food RFID are attached to food items as they are packaged and used as unique identification tags. The packaged items are placed on pallets or shelves awaiting shipment. The workers carry RFID scanners through your warehouse to complete the inventory.

RFID readers automatically collect data about each food item. It does not suffer from human errors that tend to occur with manual data entry. It uploads the read data to the asset management system and stores it there simultaneously.

RFID readers on the transfer doors read the RFID tags on the food items as they are loaded onto the trucks. You can easily have accurate data on which products leave the warehouse.

Suppose you are a milk processor and have thirteen sources of milk production. Some retailers only receive milk produced by three of them. Then with an RFID inventory system, you can easily ship the specified milk to your customers.

All food items in the warehouse are tagged with RFID tags that contain specific information. It allows you to determine the correctness of the goods quickly.

Food RFID Offers Supply Chain Benefits

We can often see information about food safety on news channels. Consumers are very sensitive to the source of food. Therefore, many issues must be taken care of, such as inventory control, legality, etc. Because of these issues, Food RFID is a good fit. RFID has clear advantages in the food industry.

RFID Food Traceability

RFID in food helps to identify and manage every kind of food, material, tray, etc. It lets us know where products are located and how much inventory is available in total or in a particular product line. It also allows us to easily know all the information related to the required conditions of the product. It includes expiration dates, consumption levels, lot numbers, and weights. Even the temperature and humidity can be easily grasped. You can track the source or route of the food supply chain by looking at the information from the RFID chip in the food package to ensure its safety.

Automated Inventory Control

The time spent loading, delivering, and receiving food products can affect the efficiency of the entire supply chain. It can also affect the safety of the product. If not tracked on time, it can have serious consequences.

RFID allows for automated inventory control. RFID in food products is automatically counted and recorded, enabling real-time inventory management. It is especially true for food products that must be kept refrigerated at all times. RFID tags in food products in the freezer store a lot of detailed information about the product. It includes how long the product has been in the freezer, its state of maturity, and the maximum time it can remain refrigerated.

RFID tags can track food products in real time, making identifying and resolving problems easy. This technology can also be used to automate inventory management, reducing the need for manual labor and minimizing human error. This helps speed up food product delivery to retailers and consumers.

Controlling Productivity

Often logistics operations are extremely inefficient due to repetitive daily tasks. With RFID, you can identify batches of products that need to be moved to a location. It also records changes in product location and quantity, helping you to locate specified products more quickly.

RFID can help you control operational efficiency and reduce operational costs. It can also add additional value to your business. One phenomenon can be seen based on the 2015 Material Handling Association’s industry report. It makes order processing 30% faster and reduces labor costs by 30%. It also allows for nearly 100% accuracy in inventory, orders, shipments, and receipts.

Packaging Recycling

It is common for the food industry to reuse trays and plastic boxes. They are usually reused after being sterilized. It may not seem very clear if you use the traditional method to record these boxes. Food RFID make it easy to solve the problem. RFID readers can identify and process trays and boxes returned through the supply chain and differentiated them.

Food RFID can benefit more than just the food supply chain. It can also bring clear advantages to restaurants and bars receiving food.

Restaurants and Bars Benefit from RFID in Food

By leveraging different applications, food RFID can help restaurants and bars in various ways. It includes everything from inventory tracking to customer service. In particular, its high-value data allows operators to target it to improve business operations. It can also help operators increase productivity and reduce operational costs. It also has more obvious benefits in the following areas.

Inventory Tracking

Inventory tracking is critical for every industry, especially restaurants and bars. Using RFID technology ensures that inventory is always fully stocked. Ingredients, drinks, and consumables will not run out. RFID tags attached to items also ensure that food is always within its shelf life and being used. After all, food can’t be stored or used for long periods. Once the shelf life has expired, people can waste new food. If consumers eat it, there are more likely to be serious consequences.

RFID tags and scanners keep inventory records up to date. People can tag Individual items, crates, or other containers with an adhesive RFID tag. It can store data, including the date people purchase the food, the best before date, and the use-by date.

Scanners placed on store shelves or at pantry doors and refrigerators can track every item in and out. It gives managers a complete view of the warehouse inventory. Managers will be able to know what items need to be reordered in the warehouse. They will also know the usage of perishable products, etc.

With this constant tracking, the warehouse can maintain adequate inventory levels. People can also use Perishable items up promptly.

RFID can also automate the entire process in the warehouse. The scanner automatically checks the inventory without you having to handle it yourself. It saves you a lot of time to do other things. The scanned information is also uploaded to the company’s asset management system. Managers can easily get the inventory information they want.

Speed of Service

Speed of service is a very important thing for restaurants and bars. Customers usually expect their food orders to be delivered quickly and accurately. Timely service also means getting more visitors.

Large restaurants usually receive the most complaints. Because they have multiple tables, rooms, and outdoor spaces, the waiter can easily get confused. Often, waitpersons need to call ahead before delivering a meal, resulting in extreme inefficiency. Delayed meals can also result in food being delivered at the wrong temperature and cause customer complaints.

Efficient service not only makes for happier customers but also for greater profitability. RFID can help restaurants improve their efficiency, which is why most are now using it. Managers can attach RFID tags to tables and service counters. Each employee is equipped with a handheld RFID scanner. When a customer comes to the service counter to order, the employee provides the customer with a smart order number card with an Food RFID tag. The staff can find the order faster with the card. Restaurants can analyze employee productivity through RFID tags at tables and service counters. The main analysis is the time it takes for the customer to receive the order and the time it takes to wait for the staff to deliver the food.

Food Ordering

RFID makes ordering orders more accurate. Employees using RFID handheld POS devices can instantly transmit dish orders to the restaurant kitchen or bar. It saves employees the time it takes to order and walk to the order placement desk. It is more accurate to double-check with the customer to confirm a noted dish than an order written on paper, and is more acceptable to the kitchen. It allows staff to have more time to help guests.

RFID handheld POS devices are also superior to devices that use WiFi. Because WiFi devices are unstable, it is easy to lose connection. It can prevent situations such as orders not going through or duplicate orders due to wireless network failure.

Time Management

RFID allows accurate tracking of hours worked by hourly billed employees. Managers can track by providing employees with RFID smart cards, wristbands, or badges. They allow managers to know exactly when employees enter and leave the office. People can even use them to track employees’ whereabouts in the field.

An RFID scanner at the entrance reads the smart card information embedded with an RFID chip. The scanner records the time the employee arrives and leaves the workplace and the number of hours worked. Managers can link this to the company’s payroll system to automate payroll payments. It can greatly reduce financial management work.

Data

RFID tags collect data and information that can be of great benefit to restaurant and bar owners. Inventory tracking can help them understand the popularity of a dish or drink and improve the menu. Table service tracking has a more obvious effect on serving customers. It can improve customer satisfaction. It can also help managers develop more effective ways to take orders. Tracking employees can also improve their productivity and reduce their on-time problems.

While the food industry may face many challenges, RFID has the potential to solve them all. RFID technology is a proven solution to many problems and is one of the most useful. It is a viable option for a complex and diverse range of products.

Q1: How is RFID used in supermarkets?

A1: RFID is used in supermarkets to track inventory and improve supply chain management. RFID tags or labels can be attached to products, and these tags can be read by RFID readers located throughout the store. This enables supermarkets to keep track of their inventory in real time, optimize their stock levels, and improve product availability.

Q2: What does RFID mean in packaging?

A2: In packaging, RFID stands for Radio-Frequency Identification, a technology that uses radio waves to transfer data between a tag or label attached to a product and a reader device. RFID in packaging can be used to improve supply chain management, enhance product tracking, and improve inventory management.

Q3: How will RFID tags be used in supermarkets instead of barcodes?

A3: RFID tags can be used in supermarkets instead of barcodes to improve inventory management and speed up the checkout process. RFID technology enables faster and more accurate scanning of products, reducing wait times for shoppers and enabling supermarkets to keep track of their inventory in real time. However, implementing RFID tags in supermarkets may require significant technological and infrastructure investments.

Q4: How do you know if a product has an RFID?

A4: To determine if a product has an RFID tag, you can look for a small label or tag attached to the product. The label or tag may have a small chip or antenna embedded, enabling it to communicate with RFID readers. Some products may also have an RFID logo or symbol printed on the packaging to indicate that it has an RFID tag. However, not all products have RFID tags, and the use of RFID technology in retail varies depending on the store and the products being sold.