Inventory tags are important because they provide a way to quickly and accurately track and manage inventory. By using tags, businesses and organizations can easily see how much of a particular product they have in stock, where it is located, and when it was last updated. This information is crucial for ensuring that inventory levels are accurate and that products are available when needed. Additionally, inventory tags can help businesses save time and money by reducing the need for manual inventory counting and tracking. By using tags, businesses can automate many inventory management processes and focus on other important tasks. This article explores the definition, types, and offers valuable tips on utilizing Inventory labels for optimal inventory control. So, let’s dive in!

Inventory tags, also known as inventory labels or inventory stickers, are physical markers or labels attached to items or storage units. They provide key information about the inventory, such as SKU (Stock Keeping Unit) numbers, descriptions, quantities, locations, and other relevant details. Inventory labels play a crucial role in organizing, tracking, and managing inventory effectively. They categorize and identify items based on specific criteria, allowing quick and accurate retrieval.

The tags maintain a clear audit trail, reducing errors and ensuring efficient inventory control. Common details found on inventory labels include SKU numbers, descriptions, quantities, and pricing information. Location information helps streamline picking and restocking processes. Barcode or QR code tags enable digital tracking, eliminating manual data entry. Expiration tags display expiry dates, minimizing waste. Inventory labels enhance efficiency and visibility and prevent shrinkage. Implementing standardized tagging systems and utilizing inventory tags optimizes inventory control, streamlines operations, and facilitates informed decision-making.

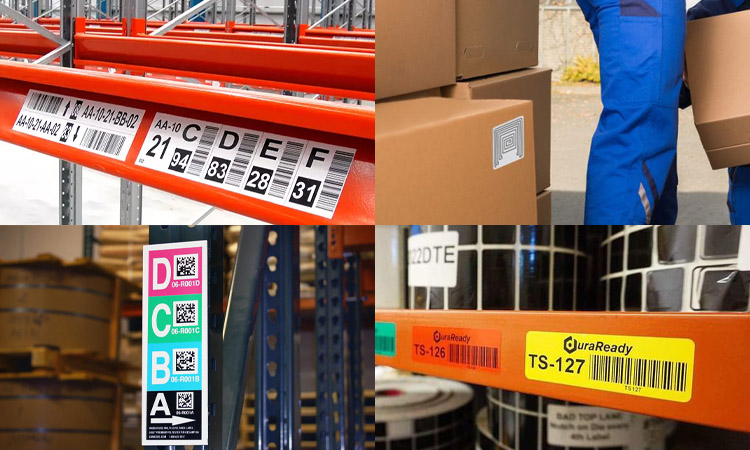

There are various types of inventory tags available, each serving a specific purpose in the inventory management process. Here are some commonly used Inventory stickers:

- SKU Tags: SKU (Stock Keeping Unit) tags are widely used in inventory management. They contain unique identifiers for each product or item in a business’s inventory. SKU tags help identify and track individual items, making managing inventory levels and monitoring stock movement easier.

- RFID tags: Radio-frequency identification (RFID) tags are inventory tags that use radio waves to transmit information about the item. RFID tags can be read using an RFID reader, allowing inventory items to be tracked without needing a direct line of sight.

- Location Tags: Location tags are used to identify and track the physical location of inventory within a warehouse or storage facility. These tags provide information about the specific aisle, shelf, or bin where an item is stored. By using location tags, businesses can streamline the picking and restocking processes, reducing search time and improving operational efficiency.

- Barcode Tags: Barcode tags consist of barcode symbols that can be scanned using a barcode scanner or mobile device with a barcode scanning app. The barcode contains encoded information about the product, such as the SKU number or other relevant details. Barcode tags enable quick and accurate data entry, enhancing inventory accuracy and expediting inventory tracking processes.

- prevent waste and ensure the proper rotation of inventory to minimize losses.

- Serialized labels: These labels include a unique serial number assigned to each inventory item. You can use the serial number to identify and track the item in the inventory system.

- Expiration Tags: Expiration tags are used for items with limited shelf life, such as perishable goods or products with expiration dates. These tags display the expiry date, allowing businesses to prioritize the sale or use of items based on their expiration status. Expiration tags help prevent waste and ensure the proper rotation of inventory to minimize losses.

- Price Tags: Price tags are commonly used in retail environments to display the selling price of items. These tags may include the product name, description, and price in a prominent and easily readable format. Price tags simplify the sales process by providing clear pricing information to customers and facilitating accurate pricing at the point of sale.

- Customizable Tags: Customizable tags are versatile and can be tailored to meet specific business requirements. They allow businesses to include various types of information, such as company logos, special instructions, additional product details, or promotional messages. Customizable tags offer flexibility in communicating specific information about the inventory.

Regardless of the type of tag you use, the important thing is that it provides a reliable and accurate way to identify and track your inventory items.

How does Inventory Control Tag Work?

An inventory control tag is a label or tag attached to an item in an inventory to help identify and track it. The tag typically includes information such as the item’s name, description, quantity, location, and other relevant details. When you add an item to your inventory, its tags are attached. The information on the label is synchronously entered into the inventory management system. This allows the item to be easily tracked and located within the inventory.

When inventory items are moved or sold, the information on the tag is updated in the inventory management system to reflect the change. This enables businesses to track their inventory levels accurately, monitor the movement of goods, and ensure items are counted correctly.

In some cases, inventory control tags may also include additional features, such as barcodes or RFID technology, to make it easier to quickly and accurately track and locate inventory items. These tags can be read using a barcode scanner or RFID reader, which allows the information on the tag to be automatically entered into the inventory management system.

Why do I Need Inventory Labels?

Inventory labels are an important part of inventory management because they provide a way to identify and track inventory items. Without inventory labels, it can be difficult or impossible to accurately track the movement and location of goods, leading to problems such as overstocking, understocking, and lost or misplaced items.

Inventory labels help businesses track their inventory levels and ensure items can be easily located and counted. They also make it easier to conduct inventory audits and other types of inventory checks, which are important for ensuring the accuracy and integrity of the inventory management system. In addition, inventory labels can help to improve efficiency and productivity by making it easier and faster to identify and track inventory items. Overall, inventory labels are an essential tool for effective inventory management.

There are several advantages to using Inventory stickers for managing inventory. Some of the main benefits include:

- Improved accuracy: Inventory stickers can help businesses and organizations track and manage inventory levels. This is important for ensuring that products are available when needed and that inventory levels are accurate.

- Time and cost savings: By using Inventory labels, businesses can automate many of their inventory management processes, saving time and money. This can free up employees to focus on other important tasks and can help businesses reduce the need for manual inventory counting and tracking.

- Better visibility: Inventory stickers can give businesses real-time visibility into their inventory levels, allowing them to see how much of a particular product they have in stock, where it is located, and when it was last updated. This can help businesses make more informed decisions about their inventory and improve their overall supply chain management.

- Increased efficiency: Inventory tags can help businesses streamline their inventory management processes and reduce the number of errors that occur. By using tags, businesses can reduce the time and effort required to manage their inventory, making their operations more efficient and cost-effective.

Overall, Inventory stickers can provide many benefits for businesses and organizations that use them to manage their inventory. By using tags, businesses can improve their inventory accuracy, save time and money, and increase their overall efficiency.

Related Articles: 11 Inventory Management Best Practices

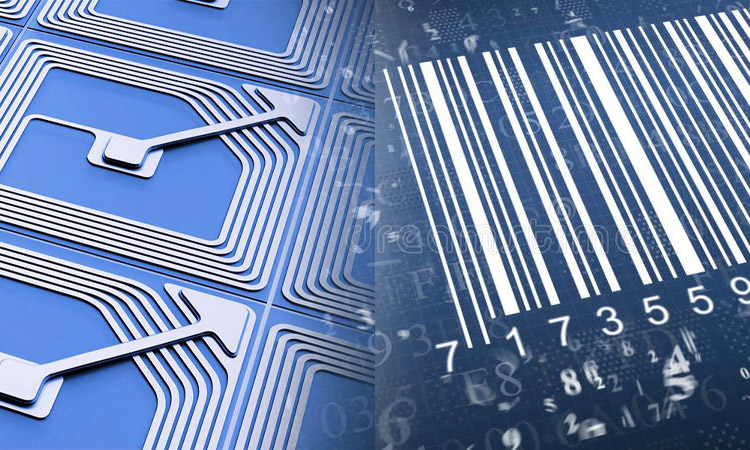

Barcodes and RFID tags have their advantages and disadvantages. Barcodes are machine-readable optical labels containing information about the item to which it is attached. They are inexpensive, easy to use, and widely available, making them a popular choice for inventory management. However, they have limited storage space, so they can only hold a small amount of information.

On the other hand, RFID tags use radio frequency technology to transmit information about an item. They have a larger storage capacity than barcodes, so that they can hold more information. They are also more durable and can be read from a greater distance, making them a good choice for tracking items in harsh environments or over long distances. However, they are more expensive than barcodes and require specialized reading equipment.

Ultimately, the choice between barcodes and RFID tags will depend on the specific needs and preferences of the business or organization using them. Some businesses may find barcodes are the best choice for their needs, while others may prefer RFID tags. It’s important to carefully consider both options’ advantages and disadvantages before deciding.

To make the most of inventory tags and ensure their effective use in your inventory management, consider the following tips:

- Consistent Tagging System: Establish a standardized tagging system across your inventory. Use consistent formats, labeling conventions, and placement of tags to ensure uniformity and ease of identification. This consistency will streamline your inventory processes and reduce confusion.

- Clear and Readable Information: Ensure that the information on the tags is clear, legible, and easily readable. Use fonts, colors, and label sizes that provide sufficient visibility. Include essential details such as SKU numbers, descriptions, quantities, and any other pertinent information that aids in quick and accurate identification.

- Barcode Integration: If using barcode tags, integrate them with barcode scanning technology. This integration enables faster and more accurate data capture, reducing manual data entry errors and enhancing overall inventory tracking and management efficiency.

- Regular Tag Maintenance: Periodically inspect and maintain your inventory tags. Check for any damage, fading, or illegibility and replace tags as needed. Regular maintenance ensures that the tags remain in good condition and continue to serve their purpose effectively.

- Tag Placement and Security: Attach the tags securely to items or storage units to prevent accidental detachment. Ensure tags are placed consistently on each item for easy visibility and retrieval. For high-value or theft-prone items, consider using tamper-evident tags or additional security measures to deter theft and protect your inventory.

- Training and Communication: Provide proper training to your staff on the importance of inventory labels and how to use them effectively. Ensure that everyone involved in the inventory management process understands the tagging system, its purpose, and the significance of accurate tag information. Effective communication and training will minimize errors and promote consistent use of inventory tags.

- Regular Audits and Updates: Conduct regular inventory audits to verify the accuracy of tag information and identify any discrepancies. Use these audits as an opportunity to update or adjust tag information as necessary. This practice helps maintain accurate inventory records and ensures that the tags reflect the current status of the inventory.

- Integration with Inventory Management Systems: Integrate your inventory labels with a robust inventory management system or software. This integration allows for seamless data synchronization, automates inventory tracking, and provides real-time visibility into inventory levels, reducing manual effort and improving overall accuracy.

Related Articles: A Beginner’s Guide to RFID Card Readers and Their Uses

Overall, using Inventory stickers involves the following:

- Attaching the tags to inventory items.

- Entering the information from the tags into the inventory management system.

- Using the information in the system to monitor and manage inventory levels.

There are several methods for removing inventory control tags, depending on the tag type and the attached material. Here are a few possible methods:

- If the tag is attached to clothing or other fabric items, it can often be removed by cutting the threads that hold it in place with scissors.

- If the tag is attached to a hard surface, such as a box or a piece of furniture, it can often be removed by using a heat source, such as a hair dryer or a heat gun, to soften the adhesive. Once the adhesive is softened, you can peel the tag off carefully with a knife or a scraper.

- If the tag is attached to a metal surface, it can sometimes be removed using a strong solvent, such as acetone or paint thinner, to dissolve the adhesive.

- If the tag is attached to a security device, such as a pin or a wire, it may be necessary to use special tools, such as pliers or wire cutters, to remove it without damaging the item.

It is important to carefully follow the tag instructions or consult a professional if you are unsure how to remove it safely and without damaging the item.

Related Articles:

Inventory tags are used in various settings to track and manage inventory. Some common use cases for Inventory labels include:

- Retail stores use inventory tags to track the quantity and location of products on their shelves.

- Warehouses and distribution centers use inventory labels to track the movement of goods and ensure that inventory levels are accurate.

- Manufacturing facilities use Inventory stickers to track the movement of raw materials, components, and finished products throughout the production process.

- Hospitals and other healthcare facilities use Inventory labels to track the location and usage of medical supplies and equipment.

- Government agencies and other organizations use Inventory labels to track the movement of assets, such as vehicles and equipment.

Overall, inventory labels are important for managing inventory and ensuring accurate tracking and inventory of products and assets.

Inventory tags are labels attached to items in inventory to identify and track them. Businesses often use these tags to manage and control their stock and can provide important information about the item, such as its name, quantity, location, or expiration date.

Inventory labels can be made of paper, plastic, or other materials. They can be attached to the item in various ways, such as adhesive, string, or a security device. Here are a few examples of Inventory labels:

- A tag on a box of groceries that includes the product name, quantity, and expiration date

- A tag on a pallet of goods that includes the product name, quantity, and location in the warehouse

- A tag on a tool that includes the serial number, model number, and date of purchase

- A tag on a piece of equipment that includes the maintenance schedule and any safety warnings

- A tag on a container of hazardous materials that include the chemical name, quantity, and handling instructions

Inventory tags are often used in warehouses, factories, and other storage facilities to help businesses keep track of their inventory and ensure that they have the right products on hand when needed.

-

Q1: What are inventory tags, and how are they used in inventory management?

A1: Inventory tags are physical labels or tags that are attached to items in inventory to identify and track them. They are used in inventory management to improve accuracy and efficiency in monitoring inventory levels, location, and movement.

-

Q2: How can Tracking labels improve accuracy and efficiency in inventory management?

A2: Tracking labels can improve accuracy and efficiency in inventory management by tracking inventory levels, location, and movement. This can help to prevent stockouts, reduce overstocking, and improve overall inventory control.

-

Q3: How can Inventory labels be integrated with other technologies, such as artificial intelligence and machine learning, to improve inventory management?

A3: Inventory labels can be integrated with other technologies, such as artificial intelligence and machine learning, to improve inventory management by providing predictive analytics, automated decision-making, and advanced data analysis capabilities. This can help to improve accuracy and efficiency in inventory management and reduce costs.

-

Q4: Are Inventory stickers safe?

A4: In general, Inventory stickers are safe to use. They are typically made of durable materials and are not harmful to handle. However, it’s always a good idea to follow any safety instructions or precautions the manufacturer provides to ensure the safe use of any product.

-

Q5: Which large companies use Inventory labels?

A5: Many large companies use Inventory labels to keep track of their inventory and assets. Some examples of large companies that might use Inventory labels include retailers, manufacturers, warehouses, and logistics companies. These companies often have large quantities of items that need to be accurately tracked and managed, and Inventory labels can help them do that efficiently and effectively.

-

Q6: Where can I purchase inventory labels?

A6: You can purchase inventory labels from various sources, including office supply stores, industrial supply stores, and online retailers. Some companies specializing in inventory management solutions may also offer inventory labels as part of their product line. It’s a good idea to shop for the best price and quality for your needs. You can also check with the manufacturer of your inventory management system to see if they offer compatible labels.

-

Q7: How do inventory tags help prevent inventory shrinkage?

A7: Inventory tags act as a deterrent to theft by indicating that inventory is monitored. During audits, the presence of tags helps identify missing items or discrepancies, allowing for immediate action. This helps prevent inventory shrinkage and protects the profitability of the business.

-

Q8: Can inventory tags be customized?

A8: Yes, inventory tags can be customized to meet specific business requirements. They can include company logos, special instructions, additional product details, or promotional messages. Customizable tags offer flexibility in communicating specific information about the inventory.

-

Q9: How often should inventory tags be maintained?

A9: Inventory tags should be regularly inspected and maintained. Check for any damage, fading, or illegibility and replace tags as needed. Regular maintenance ensures that the tags remain in good condition and continue to serve their purpose effectively.

-

Q10: Can inventory tags be integrated with inventory management systems?

A10: Yes, inventory tags can be integrated with inventory management systems or software. This integration enables seamless data synchronization, automates inventory tracking, and provides real-time visibility into inventory levels. It reduces manual effort and improves accuracy in managing inventory.